P6

Before starting work with your SAM Combo Spreader please read the following application and set-up

instructions to ensure safe and productive operation.

SPREAD RATE SETTING

The required fertiliser application rate can be set by adjusting the back door jack and viewing the spread rate sticker to

achieve the desired rate per hectare. The floor-belt speed is ground-driven from the wheel

ensuring the application rate at the desired back door setting will remain constant regardless of tractor speed.

The back door settings on the spread rate sticker are a guide only. Note, various fertiliser products will flow differ-

ently. We recommend applying the the first bin load of product onto a measured

paddock/area and carefully checking application rates to ensure spread rate accuracy.

We have included a more comprehensive spread rate chart, that includes product densities for a

selection of known fertiliser products within this manual for your reference. The spread rate (back door settings) are

typically very similar for fertiliser products of the same density and granule type.

SPREADING CENTRES

We recommend spreading at 15 metre centres for granulated fertiliser products and 10 metre centres for powered or

fine granulated products such as Lime. Within the included spread rate chart we have also included spreading rates

at 17.5 and 20 metre centres if required. For fertiliser application rates over 500kg per hectare we suggest selecting

closer spreading centres with a lower back door setting.

SPREADING ORGANIC MATERIAL

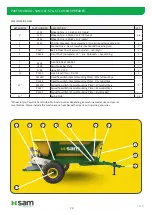

When spreading organic material we recommend removing the Vee Divider (marked A above) and bolting this onto

the holder marked B (above). When spreading chemical fertilisers the Vee Divider must always be fitted in the

original position (and not bolted to the holder).

If an internal mesh is fitted, we recommend removing it from inside the polyethelene bin when spreading

organic material, lime or urea.

GROUND DRIVE

The SAM Combo Spreader has one ground drive speed.

HYDRAULICS

Standard SAM Fertiliser Spreaders are fitted with two OMP50 hydraulic motors running in series, requiring an

external oil flow of 50 litres/minute.

It is very important that you adjust the hydraulic oil flow from the tractor back to 50 litres/minute

if possible (or 70 litres/minute maximum). Two OMP50 hydraulic motors can be run in series with hydraulic oil

SET-UP AND OPERATION - PLEASE READ

SET-UP OPERATION

A

B

Содержание 3.8 TONNE SINGLE AXLE

Страница 14: ...P14 SPREADING TABLES SPREADING TABLES ...