Page C-1

CHAPTER 4: SETUP MENU DESCRIPTIONS AND PROCEDURES

4.1

SETUP MENU DESCRIPTIONS

This section provides more detailed descriptions of the selections found in the Setup Menu Chart.

Factory-set defaults are shown in bold with a checkmark (

√

).

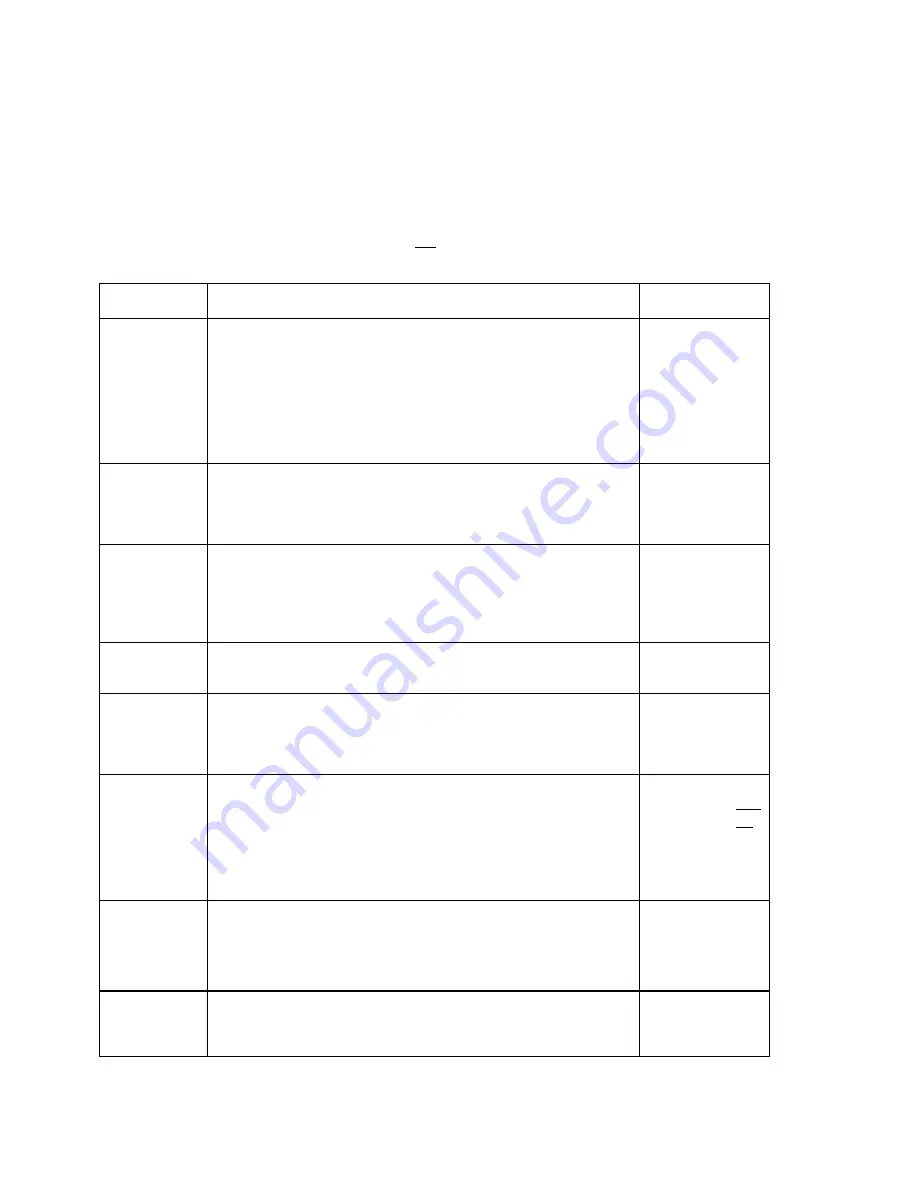

Table 4-1 shows the selections that are not allowed for “Legal-for-Trade” applications:

NAME/CODE

DESCRIPTION

CODE/VALUE

F1

Graduations

Specifies number of full-scale graduations. Value should be

consistent with legal requirements and environmental limits on the

useful system resolution.

500 1,000

1,500 2,000

2,500 3,000

4,000 5,000

6,000 8,000

10,000

√

12,000

20,000 30,000

40,000 50,000

F2

Span Gain

Span Gain is related to A/D integration time. The larger the span

gain, the higher the internal resolution, but the slower the update

speed. Note that the scale must be re-calibrated whenever this

parameter is altered. See Appendix C for more information.

25 50

75

100

√

150 200

F3

Zero Track

Band

Selects the range within which the scale will automatically zero. Note

that the scale must be in standstill to automatically zero. Selections

are in Display Divisions.

0d

0.5d

√

1d

3d

5d

F4

Zero Range

Selects the range within which the scale may be zeroed. Note that the

indicator must be in standstill to zero the scale.

100%

√

1.9%

F5

Motion Band

Sets the level at which motion is detected by comparing the present

display update with the previous one. If motion is not detected for two

seconds or more, scale is in standstill and can process a Print or Zero

command. Maximum value varies depending on local regulations.

1d

√

3d

5d

10d

F6

Digital Filter

Averages weight readings to produce higher stability. The higher the

filter number, the greater the stability but the slower the response

time. Choose 8 or 12 unless a very fast response is needed. Use the

“Auto” setting to automatically determine the filter length as you are

weighing.

Aut

o

√

1 2

4 8

12 16

32

F7

Overload Limit

Selects the desired formula which determines the point at which the

indicator shows overload. All selections are based on the primary unit

selected in F8.

"FS" = Full scale in primary units.

FS

FS + 2%

√

FS + 1d

FS + 9d

F8

Calib. Unit

Selects the primary base unit to be used in the calibration process.

Also the default unit for normal operation.

"1" = primary unit is lb. "2" = primary unit is in kg.

1

√

2

Содержание S750 Series

Страница 5: ...Page C 1...

Страница 8: ...Page C 1 FIGURE 1 1 S750 Front Panel...