FT TRUCK MT

17

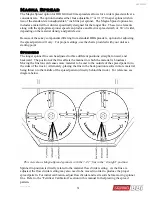

Spread patterns can also be adjusted by moving the point of delivery toward the outer edge of the

spinner or into the center. Placement of fertilizer near the outer edge of the spinner will increase

the amount of fertilizer deposited behind the spreader. Shifting the point of delivery to the

center of the spinner will increase the amount of material thrown to the sides.

The material divider should be adjusted in conjunction with spinner speed to obtain the best

spread pattern. Trial and error will help determine the correct position most of the time. After

experience is obtained with a variety of materials, the trial and error will become less and less of

an effort but never completely eliminated.

SPINNERS

Proper spinner speed adjustment is very important in obtaining good spread patterns. Its use will

depend entirely on the material being spread. Once set for a particular material, use a marker to

label the location of the flow control lever so as to avoid having to rerun the trial and error

testing for that particular material again.

Spinner Speed

On hydraulic driven spinners, the speed is controlled by a

priority valve. The priority valve can be adjusted to regulate a

constant spinner speed, as long as enough oil is being supplied

by the pump. The amount of oil being supplied to the spinner

system is directly related to the truck’s engine RPM’s. If

engine speed is too slow, then spinners will not have sufficient

oil supplied to keep them at the desired speed. Engine speed

requirements will differ for individual trucks depending on the

percentage of the P.T.O. and pump size.

Spinner speed will vary depending on the type of material

being spread. The size and weight of the particle determine the

speed required. Too high a spinner speed will dump everything

behind the truck. For finely powdered materials the speed will

be fairly low but for large particle materials, the speed may be

very high. In general, the speed will probably be in the range of

550 to 650 RPM.

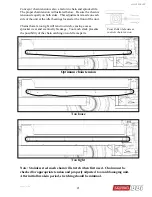

Predicting how an increase or decrease in spinner speed will affect the pattern of distribution is

difficult. This adjustment should be made only after other methods of adjustment fail to give a

satisfactory pattern. Increasing spinner speed may increase or decrease the material directly

behind the spreader, depending on the material being spread, the original spinner RPM, and type

of blade setting. Adjustments with spinner speed will be by trial and error and is less predictable

than other means of adjustment.

Perhaps the best way to adjust the spinner speed is to observe the way material spins off the

spinner. At slow speed the material leaves the blades in bands. At medium speeds it forms wide

bands in the air, and at higher speeds the bands form into one thick blur.

ADJUSTMENTS

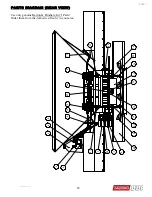

The hydraulic flow control

(priority valve) regulates

spinner speed.