37 |

Sailrite�com

Leatherwork

®

Guidebook

| 38

Needle Issues

The needle is breaking

Ensure the needle is large enough for the

thickness and type of leather being sewn� Also

make sure the point of the needle is the correct

type for the material being sewn�

Needles will also snap if there are jams or

tangles in the bobbin� Before installing your

bobbin, make sure it is wound correctly and

unwinds smoothly�

The needle hits the needle throat

plate when reversing sewing

directions

This is most likely caused by a bent needle� To

avoid bending needles when changing sewing

direction, stop the machine with the needle

positioned either at the top or bottom of its

stroke� When the needle is completely up, the

foot can move the material but cannot bend the

needle� When the needle is completely down,

the outer portion of the walking presser foot

is up and cannot move the fabric, which also

would bend the needle�

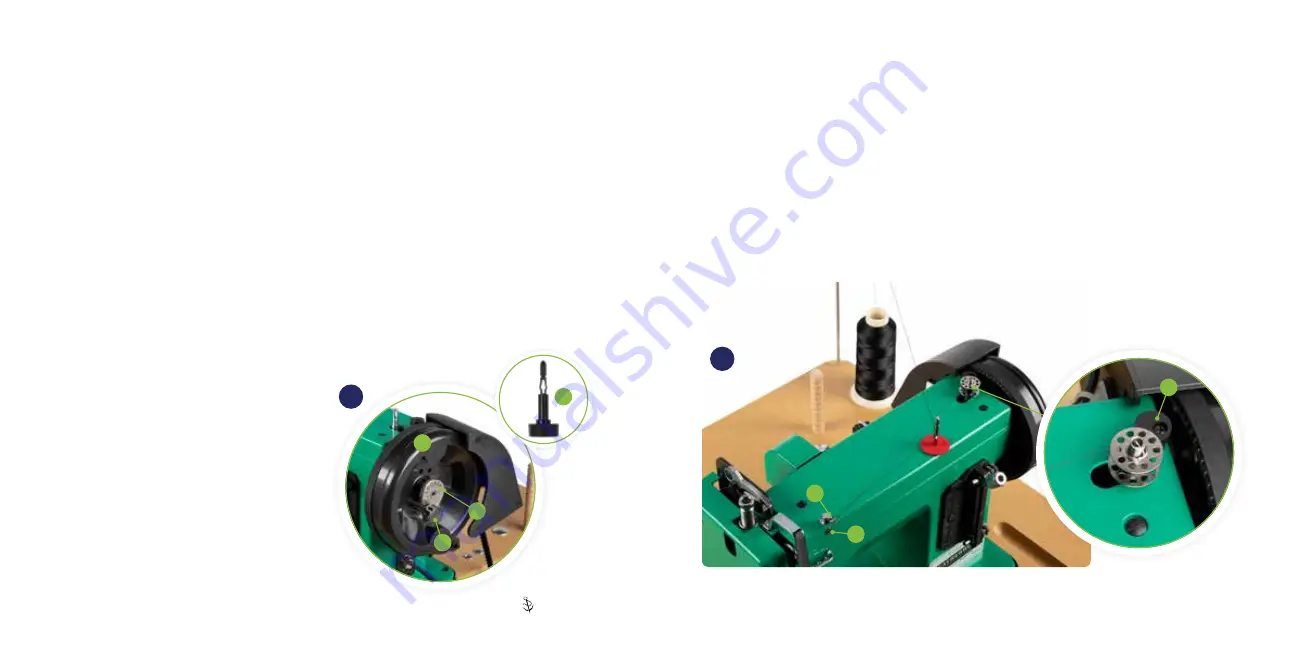

The balance wheel rotates, but the

needle does not penetrate the fabric

The Posi-Pin

®

clutch may slip if the pin is not

pushed all the way into the bushing hole that

locks the bushing to the balance wheel or if the

bushing itself is loose�

1� Make sure the Posi-Pin (

A

) is fully inserted�

2� If slipping still occurs, remove the Posi-

Pin (

A

) and Posi-Pin nut (

B

) and slide the

balance wheel (

C

) off the bushing�

Use a 2�5mm hex key to tighten the two set

screws (p� 59,

17

) that fasten the bushing to

the machine’s upper shaft, then reinstall the

balance wheel and check for proper operation�

Bobbin Winding Issues

The bobbin is not filling evenly, either

too much thread on the top or bottom

Locate the bobbin tensioner (

D

) and loosen the

screw (

E

) just under the tensioner on the front

of the machine� Move the tensioner down if the

bobbin is filling with too much thread on the

top� Move the tensioner up if there is too much

thread on the bottom� Tighten the screw after

correct positioning�

The bobbin winder stops before the

bobbin is full or after the bobbin has

too much thread

1� There is a bobbin stop (

F

) right next to the

bobbin winder� Simply loosen the screw

found on top of the black lobe and turn the

stop to change the thread fill level.

The closer the lobe is to the bobbin the

less it will fill, the further away the more it

will fill.

A

44

A

B

C

45

D

E

F

Содержание Leatherwork

Страница 1: ......