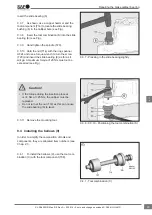

9.4.2 Insert the new bellows (9) into the holding

sleeve (T07) of the tool combination (C). Ensure

that the folds of the bellows are inside the tool

(see Fig. arrow B).

9.4.3 Insert the holding sleeve (T07) of the tool

combination (C) with the bellows (9) into the bore

and hand tighten the screw (T10) (see Fig.).

9.4.4 Then insert the bellows (9) with a maximum

torque of 8 Nm (see Fig.). Remove the tool combi-

nation C.

9.4.5 Ensure the correct seating of the bel-

lows (9). Perform a tension test (see Fig. 9.4.5).

9.4.6 Smear the brass bushing (7) and slide

bearing (6) with white grease (supplied in the repair

kit).

9.4.7 Install the guide bushings (4, 5) (see Fig.).

9.2.4 - 9.4.3 - Inserting the new bellows with

the tool combination (C) into the bore and hand

tightening T10

9.4.4 - Inserting with max. torque of 8 Nm

9.4.5 - Ensuring the correct seating of the bellows

9.4.7 - Inserting the guide bushing

Repairing the brake calliper bearing

44

en

XL-SA40001RM-en-DE Rev A • 02.2016 • Errors and changes excluded © SAF-HOLLAND