12

OPERATION

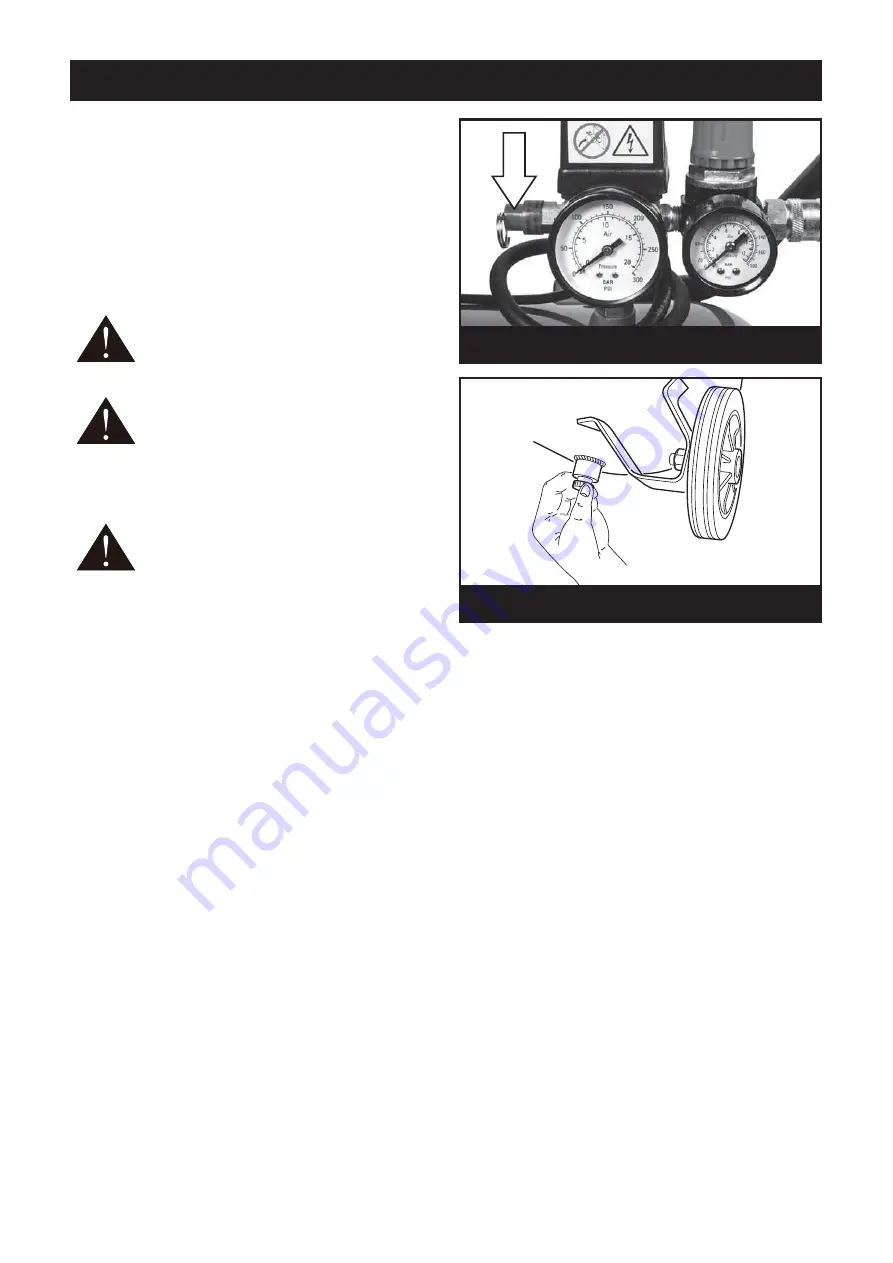

SAFETY VALVE

Check the operation of the safety valve, under

pressure, daily by pulling the ring as shown in

Fig.14. Air should be released when you pull the

ring and stop when the ring is released.

•

If the valve does not operate as described, or

if the valve is stuck, it must be replaced by

qualified service personnel before using the

compressor.

WARNING.

Do not remove or attempt to

adjust the safety valve.

DANGER.

Do not attempt to tamper with

the safety valve. Anything loosened from

this device could fly up and hit you.

Failure to heed this warning could result

in death or serious personal injury.

DRAINING THE RESERVOIR

CAUTION.

It is important to drain the

reservoir before storage to help prevent

tank corrosion.

Switch the air compressor off, by pressing the

On/Off button to the off position (pressed down),

and remove the plug from the mains supply.

Pull the ring on the safety valve to release pressure

until pressure gauge reads less than 20 psi.

Release the ring.

Place a suitable container beneath the compressor

to catch any condensation.

Carefully undo the drain valve nut anti-clockwise

until you hear a hissing noise, this is the reservoir

depressurising (Fig.15).

When the gauge indicates zero and the hissing has

stopped, tighten the drain valve nut again.

OIL CHANGING

Replace the oil after the first 100 hours of

operation and every 300 hours subsequently.

Remember to check the oil level at regular

intervals.

For changing the pump oil, be sure to do the

following:

1. Turn the unit off and unplug the power cord

from the receptacle.

2. Allow the compressor time to cool if it has been

in operation.

3. Open the drain valve to bleed all air from the

tank.

4. Close the drain valve.

5. Remove the dipstick on the pump.

6. Remove the oil drain plug with a box end

wrench or socket. Drain the oil into a suitable

container and dispose of properly. The

compressor may need to be tipped slightly

towards the drain hole to allow all of the oil to

drain.

7. Reattach the oil drain plug.

8. Refill the compressor pump with an air

compressor oil such as SAE-30 non-detergent

(API CG/CD Heavy Duty) oil at slow intervals

until the oil reaches between the minimum and

maximum marks on the dipstick. Take care not

to exceed the maximum mark. Use SAE-10

during extreme winter conditions.

Fig. 14

Fig. 15

Содержание RC-3100B

Страница 17: ...17 NOTES ...

Страница 18: ...18 NOTES ...

Страница 19: ...19 NOTES ...

Страница 20: ......