18

SETTING GAS PRESSURE

The maximum gas supply pressure to

the furnace should be 10.5

”

w.c.

natural gas, or 13

”

w.c. LP gas. The

minimum supply gas pressure to the

gas valve should be 5" w.c. natural gas

or 11" w.c. LP gas. A properly

calibrated manometer is required for

accurate gas pressure measurements.

ELEVATIONS ABOVE 2000 FT

REQUIRE THAT THE FURNACE

INPUT RATING BE ADJUSTED AND

THAT THE SIZE OF THE BURNER

ORIFICES BE RE-CALCULATED

BASED ON ELEVATION AND GAS

HEATING VALUE. THE BURNER

ORIFICES MAY (OR MAY NOT)

NEED TO BE CHANGED. SEE THE

SECTION TITLED “HIGH ALTITUDE

INSTALLATIONS” OF THIS BOOK

FOR INSTRUCTIONS.

Manifold Gas Pressure

Measurement. Natural gas manifold

pressure should be 3.5" w.c.; LP gas

manifold pressure should be 10"

w.c.

Only small variations on gas

pressure should be made by adjusting

the pressure regulator.

1. With the gas shut off at the manual

gas valve, remove the pressure

tap plug in the gas manifold or the

gas valve outlet. See Figure 26.

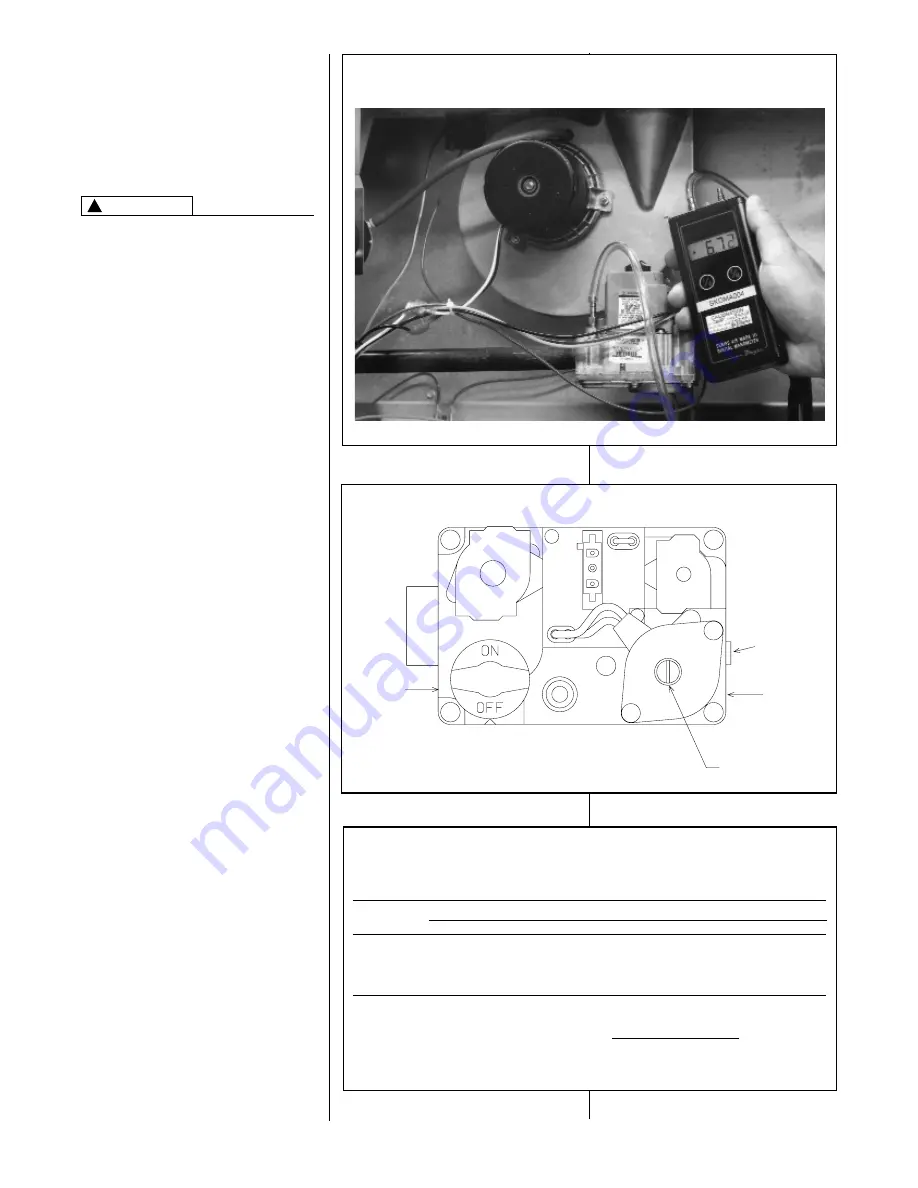

2. Connect a U-Tube manometer to

this pressure tap. See Figure 27.

3. Turn on the gas supply and

operate the furnace in high speed.

4. Note or adjust the manifold gas

pressure to give:

A. 3.5" w.c. for natural gas high fire.

B. 10" w.c. for LP gas high fire.

5. To adjust the pressure regulator

for high fire, remove the regulator

cap located on the

side of the

regulator. See Figure 14.

6. Turn the adjustment screw

clockwise to increasre pressure or

counterclockwise to decrease

pressure.

7. Securely replace the regulator cap

for high fire.

8. Operate the furnace in low speed.

9. Note or adjust the manifold

pressure to give:

A. 1.7" w.c. for natural gas low fire.

B. 4.9" w.c. for LP gas low fire.

10. To adjust the pressure regulator

for low fire, remove the regulator

cap

on the top of the regulator.

See Figure 14.

11. Turn the adjustment screw

clockwise to increase pressure or

counterclockwise to decrease

pressure.

12. Securely replace the regulator cap

for low fire.

TABLE 2

NATURAL GAS PIPE CAPACITY TABLE (CU. FT./HR.)

Capacity of gas pipe of different diameters and lengths in cu. ft. per hr. with pressure drop of 0.3 in. and specific

gravity of 0.60 (natural gas).

Nominal

Length of Pipe, Feet

Iron Pipe

Size, Inches

10

20

30

40

50

60

70

80

1/2

132

92

73

63

56

50

46

43

3/4

278

190

152

130

115

105

96

90

1

520

350

285

245

215

195

180

170

1-1/4

1,050

730

590

500

440

400

370

350

1-1/2

1,600

1,100

890

760

670

610

560

530

After the length of pipe has been determined, select the pipe size which will provide the minimum cubic feet per hour

required for the gas input rating of the furnace. By formula:

Gas Input of Furnace (BTU/HR)

Cu. Ft. Per Hr. Required

=

Heating Value of Gas (BTU/FT3)

The gas input of the furnace is marked on the furnace rating plate. The heating value of the gas (BTU/FT3) may be

determined by consulting the local natural gas utility or the LP gas supplier.

FIGURE 14

TYPICAL GAS VALVE

INLET

PRESSURE

TAP

OUTLET

PRESSURE

TAP

HIGH FIRE

MANIFOLD

PRESSURE

ADJUSTMENT

LOW FIRE

PRESSURE

MANIFOLD

ADJUSTMENT

FIGURE 13

TYPICAL HOSE CONNECTION TO LINE PRESSURE TAP

!

CAUTION

Содержание (-)GLL Series

Страница 29: ...29 FIGURE 23 COOLING HEAT PUMP OFF DELAY PROFILES ST A0827 01...

Страница 30: ...30 FIGURE 24 COOLING HEAT PUMP ON DELAY PROFILES ST A0828 01...

Страница 31: ...31 FIGURE 25 LOW HEAT OFF DELAY PROFILES ST A0829 01...

Страница 32: ...32 FIGURE 26 HIGH HEAT OFF DELAY PROFILES ST A0830 01...

Страница 37: ...37 FIGURE 32 FILTER RETAINING RODS SIDE RETURN FIGURE 33 DOWNFLOW FILTER INSTALLATION...

Страница 39: ...39 FIGURE 34 INTEGRATED FURNACE CONTROL IFC TROUBLESHOOTING GUIDE FOR UTEC 1095 101...

Страница 40: ...40...

Страница 41: ...41 FIGURE 35 FOR MODELS WITH UT ELECTRONIC CONTROLS 1095 101 INTEGRATED FURNACE CONTROL AND ECM BLOWER MOTOR...

Страница 42: ...42...

Страница 43: ...43...

Страница 44: ...44 CM 1105...