9

a. Always start the engine with a laptop connected to the ECU so that all

engine parameters can be monitored during warm-up. This also confirms all

the vital engine sensors are working.

b. Check plenty of oil is visible in the oil tank and the coolant level is to the

top of the swirl pot.

c. The engine should be dry cranked, some oil will have drained back into the

engine if it has been previously run. This will return to the tank once the

engine is started. To dry crank the engine, disconnect the ignition coils and

turn the engine over until it produces oil pressure and oil is returning to the

oil tank.

d. Once the engine is producing oil pressure and the oil is returning to the

tank, re-connect the ignition coils and turn the ignition on. Start the engine

with no throttle, then increase the engine speed to approximately 2,000rpm

–

3,000rpm. Check the oil pressure - it should be a minimum of 60 psi.

e. When the engine coolant temperature reaches 50°C, hold the engine revs

at 4,000rpm for a few seconds (this allows the scavenge system to clear oil

from the crankcases) and turn the engine off.

WARNING

–

RADIATOR COOLING FANS ARE NOT FITTED AS STANDARD. DO

NOT LET THE WATER TEMPERATURE EXCEED 90°C WHEN WARMING THE

ENGINE TO CHECK THE OIL LEVEL.

f. Immediately check the oil level, it must be between the top two marks on

the dipstick.

Re-Starting

a. Ideally, the engine should be started 45 minutes prior to going on track.

Turn the engine off when the coolant temperature reaches 85°C and allow

heat to soak into the engine. Restart 10 minutes before going on track and

get the coolant temperature to 75°C.

b. The oil level should be checked after every hour of running, and it should

be topped up to the level indicated in these instructions.

Service Intervals

Engine Oil and Oil Filter

The engine oil and filter should be changed after every 5 hours of running.

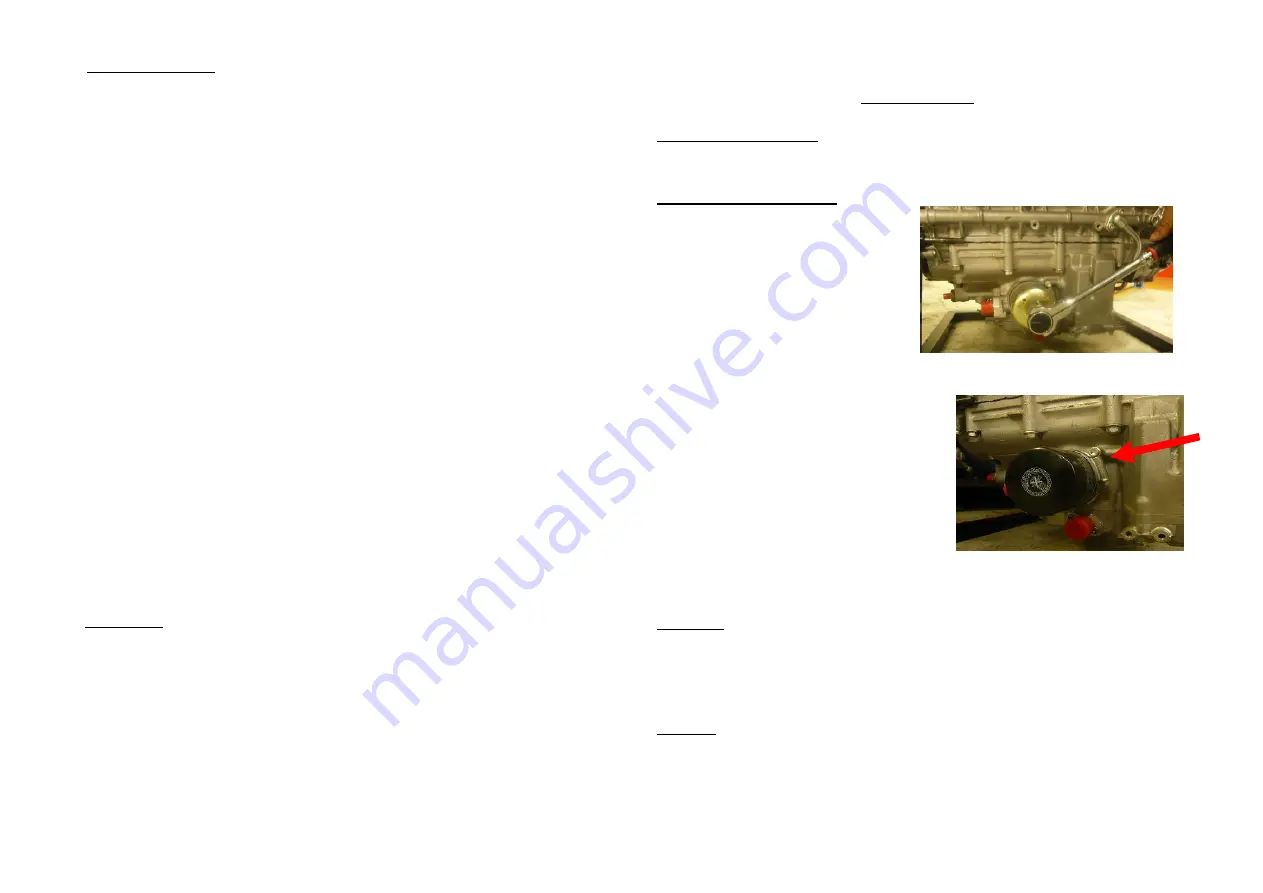

Oil Filter Fitting Procedure

1) Apply a thin film of engine oil to

the sealing o-ring on the oil filter.

2) Screw the filter on to the engine

by hand, until the o ring on the oil

filter contacts the engines surface.

3) Using an oil filter tool (shown in

picture), turn the filter another 2 turns.

4) To prevent the oil filter coming loose

during operation, a jubilee clip must be

fitted around the oil filter. The adjuster

screw housing of the jubilee clip should sit

against the bolt in the crankcases, as

shown in the picture. It should be located

hard up against the right hand side of the

bolt, as you look directly at the oil filter. If it is on the wrong side, it will not

effectively prevent the oil filter from coming loose.

Fuel Filter

The fuel filter should be cleaned after every 20 hours of running or visually

inspected - especially if you have recently fitted a new fuel tank, are

experiencing fuel starvation, or a drop in fuel pressure.

Air Filter

The engines air filter should be inspected before every race. It should then be

cleaned and oiled as per the manufacturer’s instructions and

should be

replaced as required.

Starting Procedure