13

7.

Adjust the heat input by turning the knob from the Maximum position (big flame), to the Minimum position,

as properly.

8.

After lighting, turn knob from Minimum to Maximum (big flame) position and back, to check flame stability.

9.

In case of accidental break down of the flame (for wind or other reasons), FSD will shout-off gas supply

automatically (FSD = Flame Safety Device) not over 60 seconds.

Note: The burner may be noisy when initially turned on.

To eliminate excessive noise from the burner, turn the control knob to the Minimum position and back.

If you experience any ignition problem, consult the following “Troubleshooting

”.

To turn “OFF” (full disk) the appliance

1.

Turn appliance control knob clockwise up to “OFF” position (full disk).

2.

Turn the LPG cylinder valve to the “OFF” position.

3.

Allow the appliance to cool before moving it (at least 30 minutes).

Re-Lighting

1.

Turn control knob to “OFF” position.

2.

Wait at least 5 minutes, to let gas dissipate, before attempting burner re-light.

3.

Repeat the “Lighting” steps.

LEAKAGE TESTING

Never check for gas leakages with a flame or while smoking.

This appliance needs to be periodically checked for leakages and

an immediate check is required if the smell of gas is detected.

•

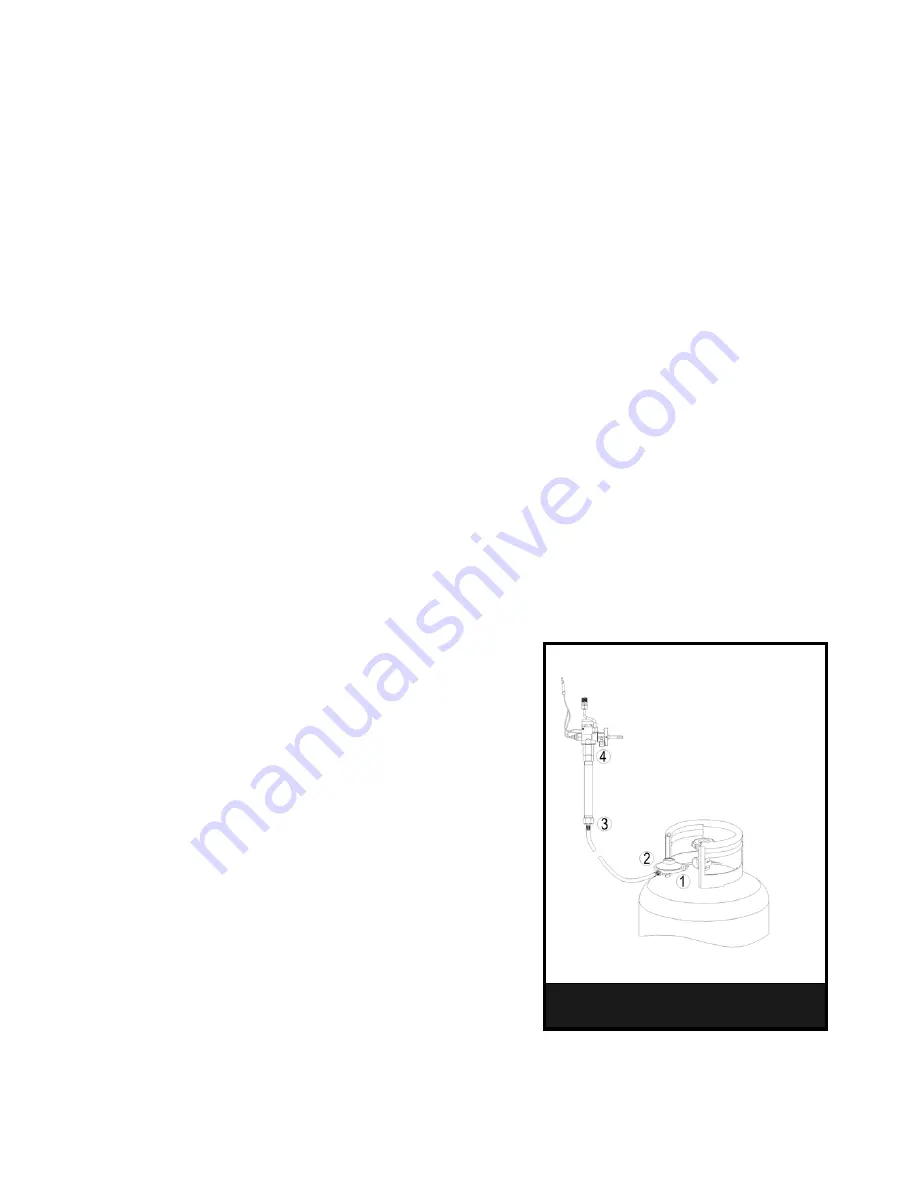

Make a soap solution using 1 part of liquid dish-washing

soap to 3 parts water. The soap solution can be applied

with a soap bottle, brush, or rag to the leakage tested

points shown in the figure beside.

•

The valve of the LPG cylinder should be in the “OFF”

position at this point of the leakage test. Once the soapy

solution is applied to the gas connections, the valve of the

LPG cylinder needs to be turned to the “ON” position.

•

Soap bubbles will begin to form in the soapy solution if any

leakage is present.

•

In the event of gas leakage, the appliance shall not be used

or if alight, the gas supply shall be shut-off and the

appliance shall be investigated and rectified before it is

used again. Tighten any leaking fittings, then turn on gas

supply and recheck.

•

If necessary, substitute gasket (according to EN 549 Class

B2) or material used to guarantee tightness (according to

EN 751-1 Class I).

Leakage Test Point

①

②

③

④