23

4

Weld sits on top, lack

of fusion

Insufficient heat input

Increase the amperage or choose a

larger electrode

Work piece dirty, contaminated

or moisture

Remove moisture and materials like

paint, grease, oil, and dirt, including

mill scale from base metal

Poor welding technique

Use the correct welding technique or

seek assistance for the correct

technique

5

Lack of penetration

Insufficient heat input

Increase the amperage or choose a

larger electrode

Poor welding technique

Use the correct welding technique or

seek assistance for the correct

technique

Poor joint preparation

Check the joint design and fit up, make

sure the material is not too thick. Seek

assistance for the correct joint design

and fit up

6

Excessive penetration

- burn through

Excessive heat input

Reduce the amperage or use a smaller

electrode

Incorrect travel speed

Try increasing the weld travel speed

7

Uneven weld

appearance

Unsteady hand, wavering hand

Use two hands where possible to

steady up, practise your technique

8

Distortion −

movement of base

metal during welding

Excessive heat input

Reduce the amperage or use a smaller

electrode

Poor welding technique

Use the correct welding technique or

seek assistance for the correct

technique

Poor joint preparation and or

joint design

Check the joint design and fit up, make

sure the material is not too thick. Seek

assistance for the correct joint design

and fit up

9

Electrode welds with

different or unusual

arc characteristic

Incorrect polarity

Change the polarity, check the

electrode manufacturer for correct

polarity

Содержание Ronch Weld 160ARC DV

Страница 1: ...1 SERIES 160ARC DV 200ARC DV STICK TIG ...

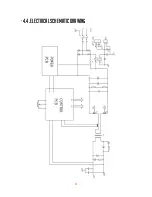

Страница 35: ...35 4 4 Electrical schematic drawing ...

Страница 36: ...36 200ARC DV STICK TIG ...