21

•

3.2.4. MMA Welding Fundamentals

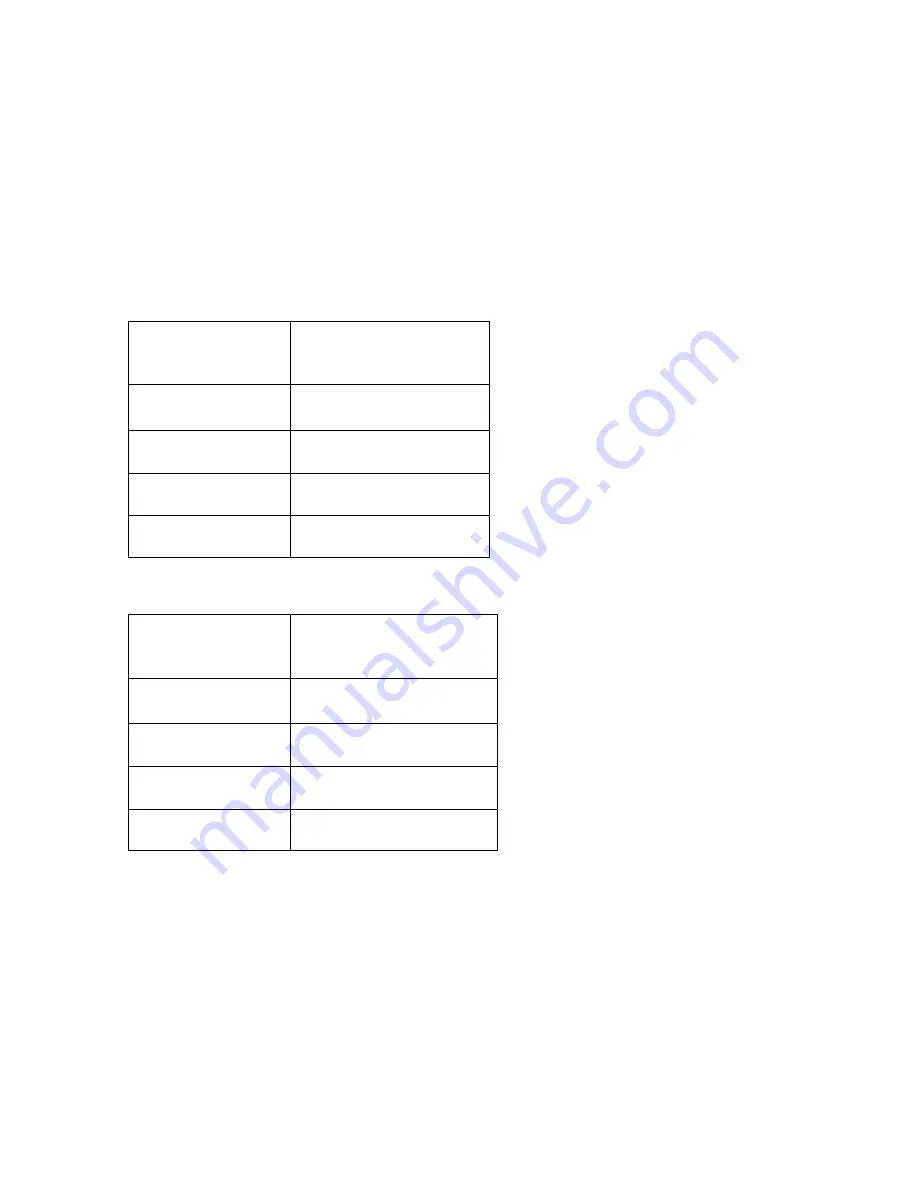

Electrode Selection

As a general rule, the selection of an electrode is straight forward, in that it is only a matter of

selecting an electrode of similar composition to the parent metal. However, for some metals there

is a choice of several electrodes, each of which has particular properties to suit specific classes of

work. It is recommend to consult your welding supplier for the correct selection of electrode.

Electrode Size

The size of the electrode generally

depends on the thickness of the section

being welded, and the thicker the section

the larger the electrode required. The

table gives the maximum size of

electrodes that maybe used for various

thicknesses of section base on using a

general purpose type 6013 electrode.

Welding Current (Amperage)

Correct current selection for a particular

job is an important factor in arc welding.

With the current set too low, difficulty is

experienced in striking and maintaining

astable arc. The electrode tends to stick

to the work, penetration is poor and

beads with a distinct rounded profile will

be deposited.Too high current is

accompanied by overheating of the

electrode resulting undercut and burning

through of the base metal and producing

excessive spatter. Normal current for a

particular job may be considered as the

maximum, which can be used without burning through the work, over-heating the electrode or

producing a rough spattered surface.The table shows current ranges generally recommended for a

general purpose type 6013 electrode.

Arc Length

To strike the arc, the electrode should be gently scraped on the work until the arc is established.

There is a simple rule for the proper arc length; it should be the shortest arc that gives a good

surface to the weld. An arc too long reduces penetration, produces spatter and gives a rough

surface finish to the weld. An excessively short arc will cause sticking of the electrode and result in

AverageThickness of

Material

MaximumRecommended

Electrode Diameter

1.0-2.0 mm

2.5 mm

2.0-5.0 mm

3.2 mm

5.0-8.0 mm

4.0 mm

>8.0 mm

5.0 mm

Electrode Size

ø mm

Current Range

(Amps)

2.5 mm

60-95

3.2 mm

100-130

4.0 mm

130-165

5.0 mm

165-260

Содержание Ronch Weld 160ARC DV

Страница 1: ...1 SERIES 160ARC DV 200ARC DV STICK TIG ...

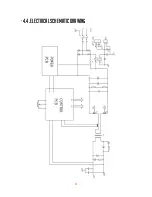

Страница 35: ...35 4 4 Electrical schematic drawing ...

Страница 36: ...36 200ARC DV STICK TIG ...