8.

Set the correction values from "H1" to "H4."

(1)

Press [

◀

] or [

▶

] to select a value from H1 to H4.

(2)

Press [

▲

] or [

▼

] to select the correction value.

H4

0

H1 H2 H3

0 0 0

(3)

When you have finished setting the correction values, press [ENTER].

The screen shown below appears again.

DETAIL SETTING

SETTING NO.1

9.

Press [

▼

] to display the screen shown below.

DETAIL SETTING

SETTING NO.2

10.

8. Set the correction values from "MEDIA GAP ADJ. NO.2 H1" to "MEDIA GAP ADJ. NO.2 H4" in the same manner as

step.

11.

Press [

▼

] to display the screen shown below.

MEDIA GAP ADJ.

TEST PRINT

12.

Press [ENTER].

Printing of the test pattern starts.

13.

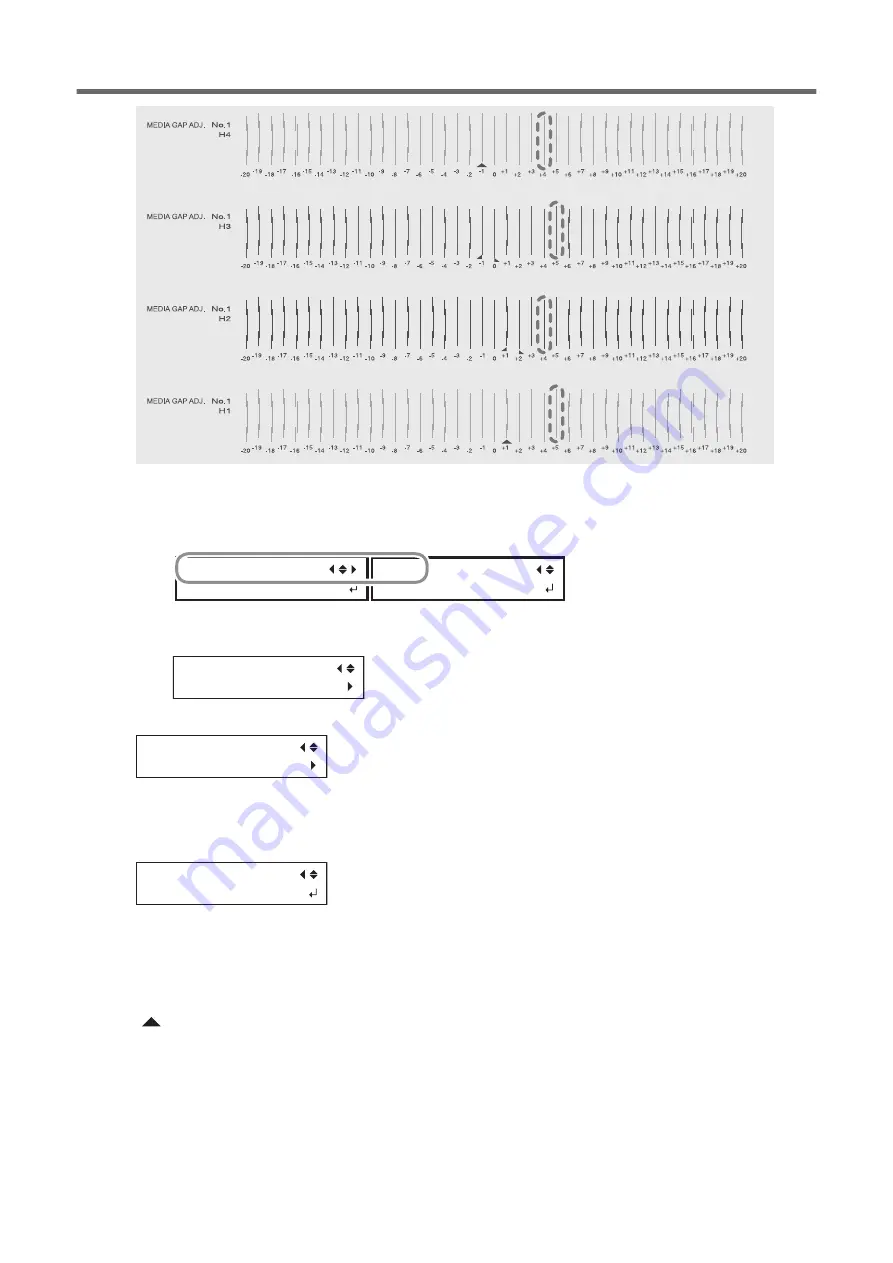

Check the test pattern to see whether the correction was successful.

For all the correction values, check that the misalignment is minimized for the two vertical lines indicated by

"

" (that is, the current correction value). If the misalignment is smaller for another set of vertical lines, set

the correction value again.

14.

When you have successfully performed the correction, press [MENU] to go back to the original screen.

What to Do First after Installation

2. Basic Operations

49

Содержание TrueVIS VG2-540

Страница 9: ...Chapter 1 Basic Handling Methods 8 ...

Страница 36: ...Setup of Media 2 Basic Operations 35 ...

Страница 43: ...Setup of Media 42 2 Basic Operations ...

Страница 60: ...Ink Pouch TR2 Cleaning Liquid Pouch Replacement 2 Basic Operations 59 ...

Страница 61: ...Chapter 2 Output Method 60 ...

Страница 70: ...REDO ADJ YES DONE 10 Press ENTER to confirm your entry Printing Output 1 Printing Method 69 ...

Страница 100: ...REDO ADJ YES DONE 10 Press ENTER to confirm your entry Printing and Cutting Output 3 Printing and Cutting Method 99 ...

Страница 122: ...REDO ADJ YES DONE 10 Press ENTER to confirm your entry Cutting with Crop Marks 4 How to Cut with Crop Marks 121 ...

Страница 138: ...Chapter 3 Optimizing Quality and Efficiency 137 ...

Страница 195: ...W1100mm B Adjusting the Output start Location 194 2 Optimizing Work Efficiency ...

Страница 217: ...Chapter 4 Maintenance 216 ...

Страница 272: ...Chapter 5 Troubleshooting Methods 271 ...

Страница 305: ...Chapter 6 Appendix 304 ...

Страница 308: ...8 Detach the blade holder Preparing to Move the Machine 1 Operations When Moving the Unit 307 ...