Assembly and installation

10

2

guaranteed to handle the K18 unit's anti-icing cycle. This

requires that a outlet/inlet bypass be installed, with over-

pressure valve set to open only when all zone valves are

closed.

All temperature probes (GHP, GHP’, B1, B3, B12) must be

placed and fixed in dedicated thermowells, with a length

suitable to result immersed in water flow or in water

mass, using thermal paste to ensure a good heat transfer.

In case one of the optional DHW preparation tanks is

used (code OSRB012 or OSRB004), it is recommended to

use the thermowell just above mid height for the probe

B3.

Even in case other water tanks are used, place probe

B3 in an intermediate position, possibly just above mid

height.

Following installation of the KECSK18 expansion kit,

the K18 system controller is automatically configured

to facilitate the installation and commissioning of the

types of circuit indicated in fig. 1.1

p. 6, 1.2 p. 7,

1.3

p. 8 and 1.4 p. 9. However, it can also support

other configurations. For applications other than those

indicated in this manual, Robur provides custom consul-

tancy service.

2

ASSEMBLY AND INSTALLATION

The Expansion kit for the K18 system controller is supplied com-

plete with everything required for quick installation inside the

CSK18 enclosure.

Before installing the unit, check that the equipment is

not connected to its power supply.

The cabling must satisfy the requirements of safety class

II, i�e� the mains power cables and the SELV cables

must be ducted separately.

Also, keep a distance of at least 50 mm between the

ducts that contain mains cables and those which con-

tain safety extra low voltage cables and between the

two categories of cables inside the enclosure; achieve

this by following the instructions provided in the Instal-

lation Manual of the System Controller with regards to

the choice of the input holes in the enclosure to use for

the mains connections and for the safety extra low volt-

age (SELV) ones.

The CSK18 and any other equipment and accessories

must be powered up only when the installation is com-

plete. Failure to observe this instruction incurs a risk of

electrocution and short-circuit.

The CSK18 must not be exposed to water.

The unit's ambient operating temperature range is 0 °C

- 50 °C.

2.1

INSTALLING THE EXPANSION KIT INTO

THE CSK18 ENCLOSURE

Assembly and installation

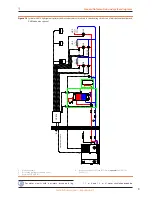

1� As shown in fig. 2.1 p. 10, assemble the AVS55.196 elec-

tronic board with the plastic mounting plate; push the six

short retainers fully into the holes in the board until the

pawls click.

The Expansion kit may also be supplied with the elec-

tronic board and mounting plate assembled together; in

this case, go directly to the next step.

Figure 2�1

Assembling the AVS55.196 electronic board with the

mounting plate

DO NOT remove the RVS21.826 board from the CSK18

enclosure.

2� Align the six long retainers on the bottom side of the mount-

ing plate with the holes in the RVS 21.826 electronic board

already present in the CSK18 enclosure, then push them in

until they snap into place.

Figure 2�2

Detail of the two boards assembled together

3� Push the connectors of the included AVS82.496 ribbon cable

fully in the comb connectors marked X100, on the edge of

the two electronic boards.

The Expansion kit may also be supplied with the ribbon

cable already assembled to connector X100 of the