Installation and user manual

Error! Use the Home tab to apply

Titolo 1 to the text that you want to

appear here.

25

7.1.3

Gas valve regulation

To adjust the gas valve, follow this procedure:

1.

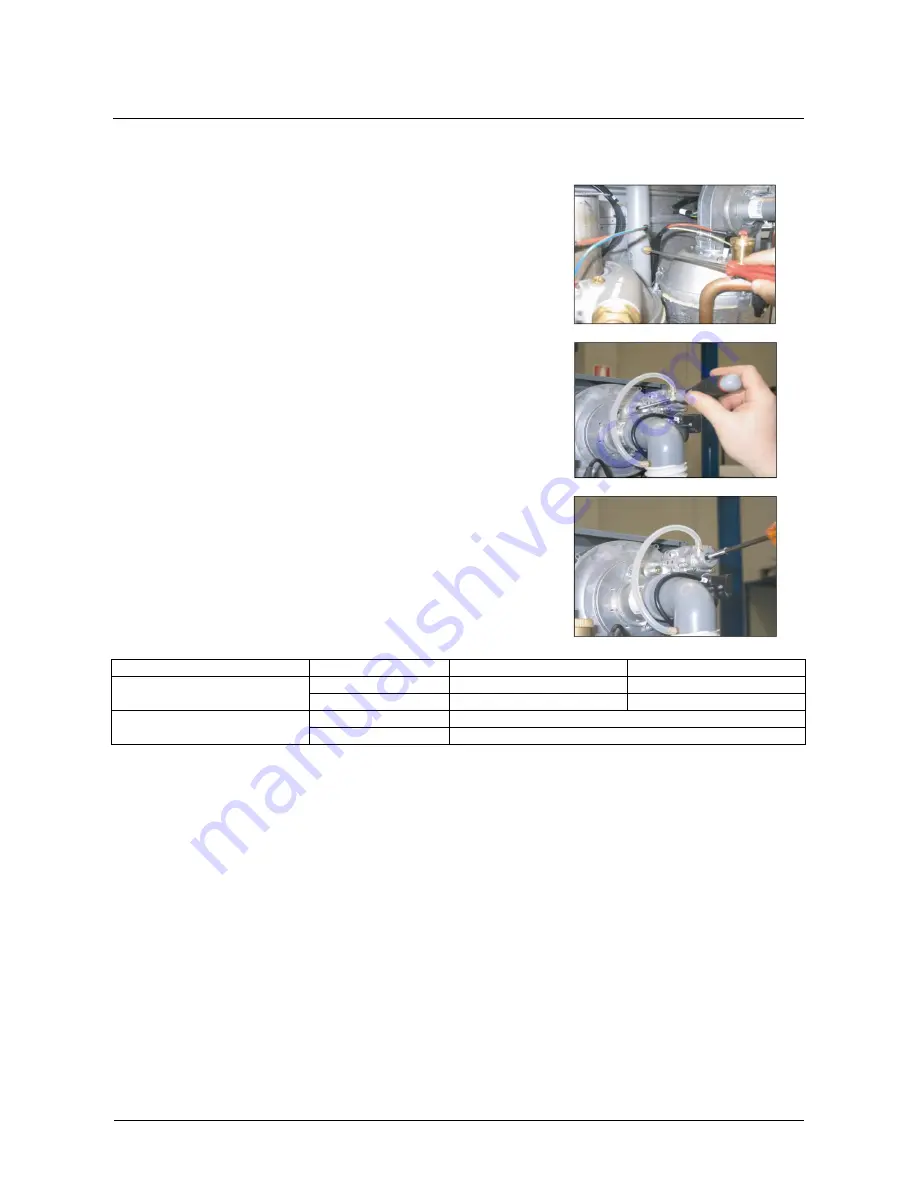

Put the flue sensor into the flue system. (Figure 35)

2.

Rotate the Venturi gas regulation screw (throttle) with two

turns on the left as shown in Figure 36.

3.

Make sure that there is a request from at least one of the

two room thermostat. If you have problems with the thermal

assembly ignition rotate on the right the regulation screw, only one

turn at time.

4.

Give the maximum power to the boiler by using the digital

control panel: you have to press at the same time S2 key

(SET/ESC) and S4 key (+) just for 5 sec. Then it’s possible to

indicate the maximum fan speed by using the S4 key (par. n°15).

All the system fans will work with this selected speed. On the first

digit on the left it’s shown the selected speed. H = maximum speed.

Other two digit will show the water flow temperature (example

T1=80°C).

5.

Regulate the combustion acting on throttle (Figure 36) until

you arrive to the nominal CO2 value shown in the below table.

NOTE. To increase the gas flow rotate on the left while to decrease

the gas flow rotate on the right.

6.

Let the boiler arrive to the maximum power and then

change, if it’s necessary, the Venturi regulation.

7.

Let the boiler arrive to the minimum power by using S5 key

(-).

8.

On left of the display it will appear a “L“ (Low= minimum

power); act on the gas regulation screw Offset (see Figure 37) to

arrive to the values present in the below table.

NOTE. To increase the gas flow rotate on the right while to

decrease the gas flow rotate on the left.

Figure 35

Figure 36

Figure 37

MODEL

GAS

MAX POWER

MIN POWER

Condensing 100

Methane

CO

2

= 9.2

– 9.4%

CO

2

= 8.3

– 8.5%

LPG

CO

2

= 10.2

– 10.4%

CO

2

= 8.6

– 8.9%

Condensing 100

(serial number 312670001)

Methane

CO

2

= 9.0%

LPG

CO

2

= 10.4%

7.2 Slave boards setting

Each slave (one for each burner) needs to be properly configured so that the Master board shall detect their

right sequence. First of all slave boards needs to be divided into blocks; the system can manage until 15

blocks made of 4 slaves each.

Ex. If 5 slaves are connected to one Master, we have 2 blocks: the first is made of 4 salves and the second

of one slave.

As a consequence, complete the following procedure to fulfil the address configuration:

1.

Locate the slave position inside each block ( ex. position1,2,3 or 4).

2.

Locate the block the slave is related to (ex. Block n°1, n°2…………till block n°15)

3.

Supply each Caldaria Condensing 100 series composing the battery.

As indicated in Figure 38, to set block address we refer to the jumper J17, while for the slaves (singles

burners) we refer to the jumper J10.

Содержание CALDARIA CONDENSING 100

Страница 38: ...Installation and user manual...