28

VENTBOSS

•

SERIES 300 SPACE SAVER COLLECTORS OWNER’S MANUAL

APPENDIX A:

INSTALLATION, OPERATION & MAINTENANCE

(continued)

Using Your VentBoss Fume Arm

The construction guarantees a safe and reliable function without continuous servicing and

special handling. The adjustment of the ERGO extraction arm consists mainly in corrections

within the frictional joints. The frictional brakes are placed in each joint of the d evice and

their function is to give the balance and self-supporting properties of the whole extraction

arm and ensure an easy manoeuvring during the operation.

The adjustment of the frictional brakes is carried out by increasing or reducing the tension of

the nuts upon the frictional elements.

The brake adjustment in the following joints ought to be executed in such a way that it

guarantees the stability and self-supporting features of the extraction arm (which is important

to keep the stable arm position), whereas on the other hand this cannot cause any excessive

resistance while User is changing the arm position. Having completed the adjustment, tighten

up the counter-nut. The placement of the adjustment nuts is illustrated in the “VentBoss

Extraction Arms – Dimensional Drawings” (Diagram 1—Appendix A).

Safety

The VentBoss extraction arms will not cause any risk provided that they are firmly and

correctly mounted to the wall or another structural element of the building.

CAUTION!

Unsure installing could cause uncontrolled detachment

of the device and be serious risk to personnel / people in the vicinity.

Having completed the work, leave the extraction arm in the ultimate operational position, in

case when it constitutes obstacle to personnel/User, set in into the home position.

Prior to installing check the load carrying capacity of the building structure.

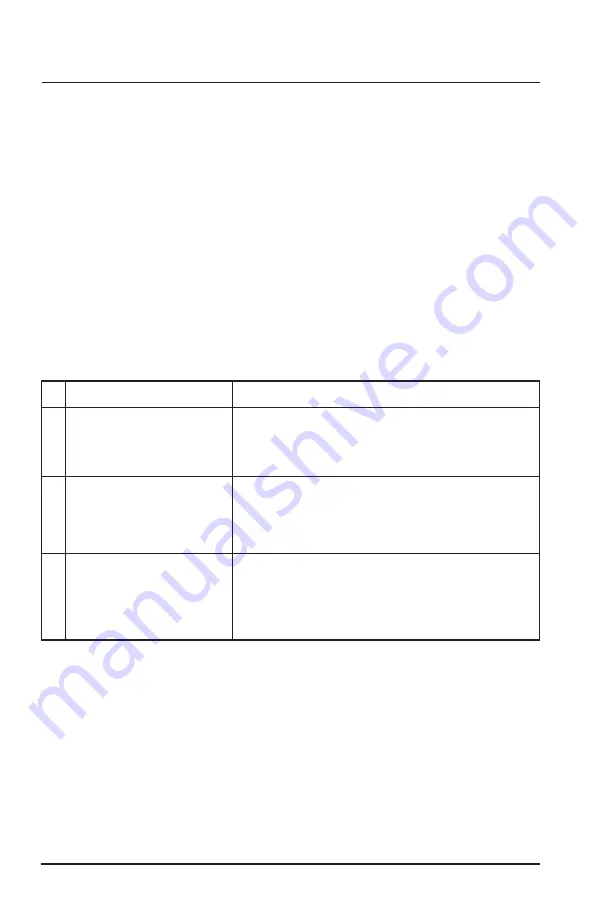

Type

1. The extraction arm is falling.

2. The extraction arm is

automatically setting always

in the same position.

3. Drop in the air suction rate

along with the increased

noise level.

Possible Reason & Corrective Action

-Improperly adjusted frictional brake.

-Increase the tension upon frictional disks of the brake

in the joint by tightening the adjustment nuts.

-The rotation axis of the arm is not positioned vertically.

-Carry out the positioning of the mounting flange of the

ERGO extraction arm to set the rotation axis vertically.

-Improper impeller rotation sense of the extraction fan.

-Change the phase connection sequence (only 3-phase

motor). If the mesh holes of the inlet net are clogged,

clean them using a wire brush.

Содержание VentBoss 300 Series

Страница 2: ......

Страница 20: ......

Страница 21: ...APPENDIX A FUME ARM INSTALLATION OPERATION MAINTENANCE ...

Страница 32: ... 2017 RoboVent 37900 MOUND ROAD STERLING HEIGHTS MICHIGAN 48310 USA 855 558 VENT WWW VENTBOSS COM ...