15

The RoadHog uses a high tension Kevlar back-

banded double V belt. Proper tensioning is criti-

cal to milling performance and belt life. It should

never be replaced with a standard V belt.

The belt tensioning should be checked after the

first 15 hours of operation and every 100 hours

after that. These same guidelines should be fol-

lowed if a new belt is installed. The tension be

checked and reset any time the belt is removed

and reinstalled.

There are two methods of checking the belt ten-

sion. One is with a sonic tension meter and the

other is with a double barreled hand tension me-

ter. The hand tester is shipped with the roadhog.

The sonic tension meter is available for purchase

from your RoadHog dealer.

Part number is SO-0249

Procedure with Gates 507C Sonic tension

Meter, part number SO-0249, purchased from

your dealer

1. Remove both upper and lower portions of the

belt shroud.

2. Loosen 4 bolts that hold the engine cradle to

the milling head chassis. 2 bolts are pivot

bolts and 2 are in slots on the front of the cra-

dle.

3. Loosen 2 jam nuts on engine cradle adjusting

bolts.

4. Connect Microphone to meter and press

POWER to turn meter on.

5. Press Hz to switch readout to Hertz.

6. Press MEASURE. Display should change to

a horizontal line.

7. Hold the microphone about ½ inch away from

belt at the midpoint of the front span of the

belt. Strike the belt with hand.

8. Horizontal line on meter will change to a wavy

line and read out the belt frequency in Hertz.

9. Meter will not read a frequency less than 15

Hz, so belt has to be fairly tight before the

meter can read the frequency. Also, high

ambient noise levels can prevent the meter

from reading the frequency.

10. Adjust two adjustment bolts on engine cradle

to adjust belt tension.

11. Repeat steps 6 through 9 until belt tension is

42-44 Hz for a new belt and 39-41 Hz for a

used belt ( more than 15 hours ).

12. Tighten 4 engine cradle bolts and tighten jam

nuts on adjusting bolts.

Procedure with non-Sonic tension tester, part

number 106-3842, shipped with your RoadHog.

1. Remove the outer shroud of the belt guard and

measure the distance from the top of the belt to

the notch cut out in the belt shroud.

2. On the scale reading “Inches of Span Length”,

set the “O”-rings to show the measurement just

taken in step one plus 0.39” of deflection.

3. At the center of the span between the pulleys

which is identified by the notch cut out in the

belt shroud, apply force, with the tension tester

perpendicular to the span, enough to deflect the

belt until the bottom edge of the “O” Rings are

even with the top of the back belt shroud.

4. Find the amount of deflection force on the up-

per scales of the tension tester, The total force

will be the sum of the readings on each of the

two scales. The sliding Rubber “O” Rings slide

up scale as the tool compresses—and stay up

for accurate reading of pounds of force. Read

the bottom edge of the rings (Slide rings down

before reusing).

5. Compare the total deflection force, it should be

between

33 to 36 lbs

on a new belt (

28 to 30

lbs

on a used belt ). If

less

than

minimum

rec-

ommended deflection force, belt should be

tightened. If

more

that

maximum

recommend-

ed deflection force, drive is tighter than neces-

sary and can damage the bearing in the drive

system.

NOTE: There normally will be a rapid drop in

tension during the “break-in period” for V-belt

drives. Check tension frequently during the first

day of operations.

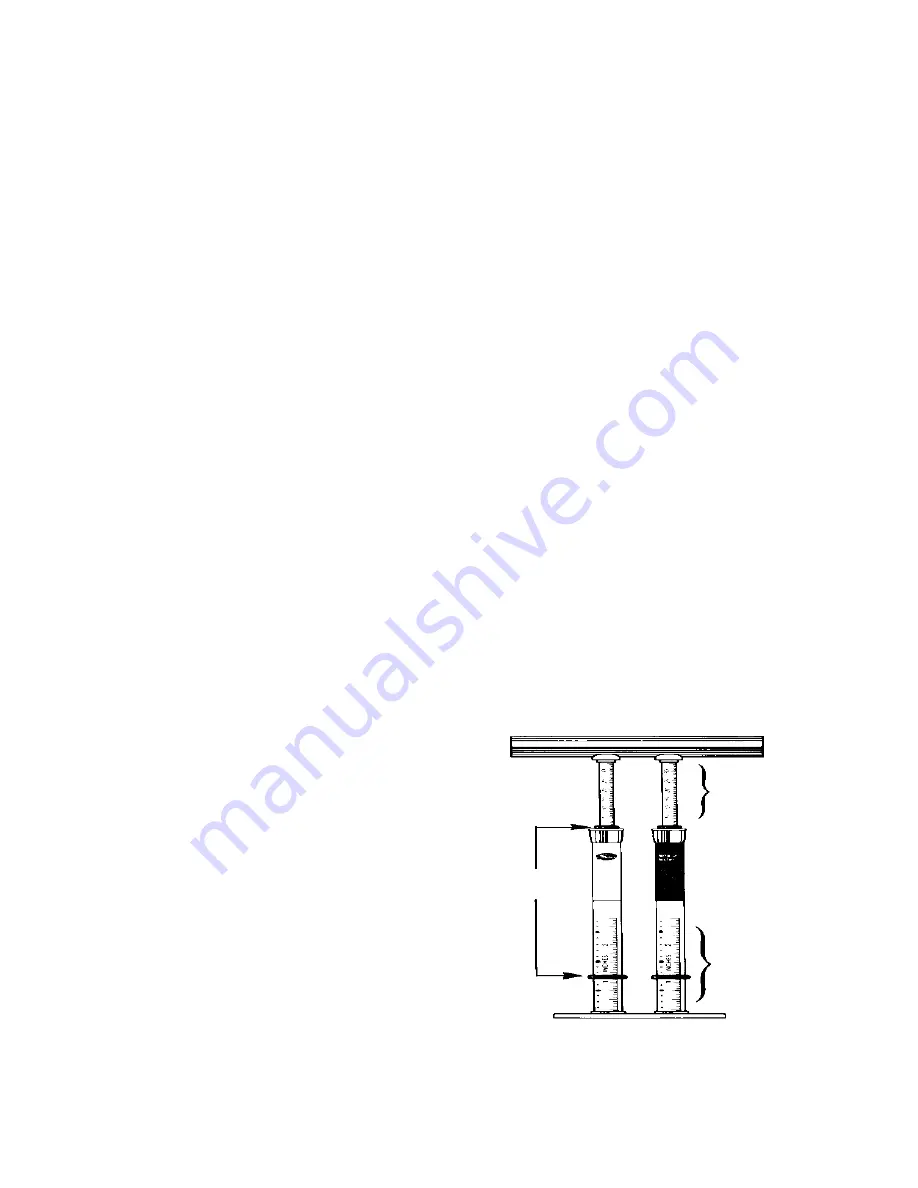

Def lection

Force Scale

(Read Up)

Def lection

Distance Scale

(Read Up)

Sliding

Rubber

“O” Rings

Read the scales at the bottom edge of

the “O” Ring. Leave the upper “O”

Ring in maximum “down” position