40

Pub. 1147 - Rev. 7 SEPTEMBER 2004

Mechanical Dock Leveler Hydraulic Conversion

Problem

Probable Cause

Remedy

2. Platform does not raise (motor running) c. Hydraulic fluid level is low.

c.Check oil level in tank.

-Continued.

Refill if there is less than 3-1/2" of

oil in the tank when the unit is held

open with the SAFE-T-STRUT™. Do

not exceed maximum oil level

indicated by the “Oil Level” decal on

the reservoir (approximately 3-1/2"

depth).

d. System leak.

d.Check hoses, fittings, valves and

power unit for leaks.

e. The motor voltage is not correct.

e.Compare customer power supply to

motor requirements.

Compare customer power supply to

control box ratings.

f. Weight on platform.

f. Remove weight.

g. Shuttle valve is not adjusted properly.

g.Readjust shuttle valve.

h. Adjustable system relief valve pressure h.Readjust until the relief pressure is

is set too low.

1200 psi.

i. Debris in the hydraulic system.

i.Drain the oil from the power unit,

hoses and cylinders and replace with

fresh oil. Verify that the suction filter in

the tank is not clogged.

j. Platform cylinder failure.

j. Replace platform cylinder.

3. Leveler runs continuously when

a. ARTD cam is out of adjustment or

a. Readjust ARTD cam.

power is turned on.

damaged.

b. The ARTD system has failed.

b.Verify that ARTD and restrictor limit

switches are functional. Type 2 Control

Box – Verify that the limit switches are

wired to terminals 3 and 4. Verify that

ARTD actuator assembly is functional.

c. The pushbutton and or contact block

c.Type 1 Control Box – Replace switch

does not function properly.

and/or pushbutton operator.

Type 2 Control Box – Replace

pushbutton and/or contact block.

d. The solid-state motor controller has

d.Type 1 Control Box – Not applicable.

had an internal failure.

Type 2 Control Box – Replace solid-

state motor controller.

4. Lip extends slowly and/or does not

a. Debris on lip hinge.

a.Remove dirt, debris and corrosion from

fully extend.

the lip hinge spools.

b. Lack of lubrication.

b.Without grease fittings – Lubricate the

hinge spools with SAE30 oil.

With grease fittings – Lubricate the

hinge spools with moly based grease.

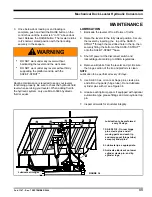

W h e n c h e c k i n g f o r a h y d r a u l i c s y s t e m

l e a k , f i r s t l o o k f o r t h e w e t h o s e s o r

f i t t i n g s w i t h o u t t h e p o w e r u n i t r u n n i n g .

O n c e t h e s u s p e c t e d l e a k h a s b e e n

l o c a t e d , h a v e a n a s s i s t a n t p o w e r - u p

t h e p u m p . M O V E A P I E C E O F C A R D -

B O A R D A R O U N D T H E S U S P E C T E D

LEAK TO LOCATE THE FAULTY PART.

DO NOT USE YOUR HAND. MAKE

S U R E T O K E E P H A N D S , A R M S A N D

FACE AWAY FROM THE AREA OF THE

S U S P E C T E D L E A K . H i g h p r e s s u r e

h y d r a u l i c f l u i d c a n b e a n i n v i s i b l e

s p r a y t h a t w i l l p e n e t r a t e f l e s h .

WARNING