Pub. 1147 - Rev. 7 SEPTEMBER 2004

5

Mechanical Dock Leveler Hydraulic Conversion

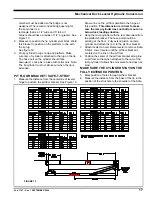

See Figure 1 for locations of these features

LIP

The extendible portion of the dock leveler which provides

a bridge from the platform to the bed of the trailer. A

hole is drilled in the lip to allow the insertion of the RITE-

HITE

®

SAFE-T-STRUT

TM

. Additional details on the SAFE-

T-STRUT

TM

are given later in this section.

LIP KEEPERS

The lip keepers provide structural support when the lip is

not on the bed of a trailer. They provide support at dock

end loads for cross traffic and maintain security for the

dock position when not in use.

SUBFRAME

The subframe of the leveler supports the platform and

protects the motor and the hydraulic fluid reservoir.

PLATFORM

The platform, along with the extended lip, provides the

main bridge between the dock and the trailer bed. It is

hinged at the rear of the subframe, and automatically

adjusts with the position of the trailer bed.

RAMP LIFTING CYLINDER

The ramp lifting cylinder is a single acting hydraulic

piston of heavy duty construction grade, non-adjustable,

with a 3-1/2” diameter piston and a 1-1/2” diameter rod.

When the power unit is energized, the cylinder extends,

lifting the platform. When power is removed, the

platforms weight compresses the cylinder, allowing the

entire unit to float onto the bed of a trailer.

POWER UNIT

This is the motor and pump which delivers hydraulic fluid

to the ramp lifting cylinder and lip cylinder. The power

unit package consists of a 3/4 hp electric motor, a 1.4

GPM gear pump, a 1.0 gallon capacity hydraulic fluid

reservoir, and all valving. The hydraulic oil reservoir

contains a top mounting combination breather filter cap.

Hydraulic oil can be added to the system by removing

the cap and pouring oil into the reservoir.

NOTE

When adding oil, use only MIL-H-5606.

SAFETY STOP SYSTEM

The hydraulic system has an emergency flow control

stopping valve (velocity fuse) that prevents the leveler

from “ free-falling” in emergency conditions. The valve is

hard piped in line with the hydraulic oil hose at the ramp

lifting cylinder.

SAFE-T-STRUT

TM

AND BASE

The hydraulic conversion is shipped with the RITE-HITE

®

SAFE-T-STRUT

TM

. This SAFE-T-STRUT

TM

is inserted

through a pre-drilled hole in the lip and then secured by

placing the end of the strut in the SAFE-T-STRUT

TM

base. The SAFE-T-STRUT

TM

increases the level of

safety for workers when installing equipment if

performing routine maintenance, and must be used

every time service is being performed on the unit.

AUTOMATIC RETURN TO DOCK

(ARTD) SYSTEM (OPTIONAL)

The dock leveler will automatically return to dock from

any position if the lip has been fully extended and a truck

leaves the loading dock. As the leveler lip lowers toward

the pendant position, the lip cylinder retracts, moving the

rotary cam assembly backward. The rotary cam contacts

the limit switch, closing the switch, activating the

hydraulic power unit and raising the leveler. As soon as

the lip has lowered to the fully pendant position, the cam

block moves past the limit switch, releasing the switch

and shutting off the hydraulic power unit. The leveler

returns to the stored position with the pendant lip

lowering into the lip supports.

ARTD LIMIT SWITCH (OPTIONAL)

This switch controls the power unit during recycle. The

rotary cam contacts the limit switch, closing the switch,

activating the hydraulic power unit and raising the

leveler. As soon as the lip has lowered to the fully

pendant position, the cam block moves past the limit

switch, releasing the switch and shutting off the hydraulic

power unit.