Page 7

10

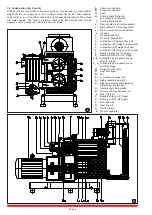

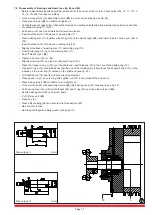

5.2.3 Electrical connections for the motor and control equipment

All electrical connections for the motor and control equipment are located in the terminal box. Each connection terminal is

numbered and these correspond as designated for each control item (as shown in the circuit diagram fig. 10). If any work is carried

out then the re-connection should be in accordance with this numbering system. Problems with function can be prevented and

faults are easier to find.

5.2.4 Terminal Box Connections Closed Circuit Cooling

Fresh or External Cooling without Fanmotor

➝

without fan motor and

operating thermostat

5.2 Electrical Installation

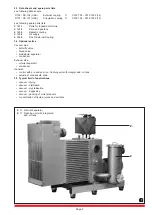

5.2.1 General (see data sheets D 131 + D 137)

The electrical data can be found on the data plate (N) or the motor data plate. The motors correspond to DIN / VDE 0530 and have

IP 54 protection and insulation class B or F. The connection diagram can be found in the terminal box on the motor. Check the

electrical data of the motor and the control gear for compatibility with your available supply (voltage, frequency, permissible current

etc.).

Connect the motor to the incoming supply. It is advisable to use thermal overload motor starters to protect the motor and wiring.

All cabling used on starters should be secured with good quality cable clamps.

We recommend that motor starters should be used that are fitted with a time delayed trip resulting from running beyond the

amperage setting. When the unit is started cold overamperage may occur for a short time.

The electrical installation must only be carried out by a qualified electrician under the observance of EN 60204. The

main switch must be provided by the operator.

5.2.2 Approximate values for setting motor overload protection

The approximate values for setting motor overload protection should be obtained from the motor manufacturer or

motor nameplate.

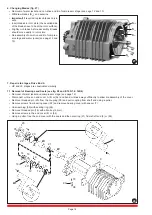

1

2

3

4

5

6

7

8

9

10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26

X1

Suction valve

Bleeding valve

V

alve flushing unit

V

alve fr

esh oil

V

alve oil mist separator

Reserve

Safety ther

mostat

Operating ther

mostat

Level pr

e-separator

Level flushing liquid

Level cooling water

Level oil mist separator

Level fr

esh oil

Reserve