Page 17

34

Y

65

Y

66

33

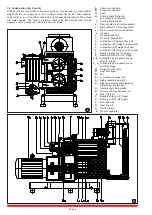

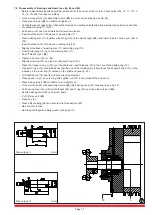

8.3 Changing Bearings, Shaft Seals and Seals in Gearbox Connection housing (fig. 33).

• Removal and re-assembly of water jacket

and compressor stage (see page 12).

• Removal and re-assembly of gearbox (see

page 17).

• Remove the circlip (87) on the drive shaft

(72) and on the gear shaft (74).

• Remove the coupling (86).

• Remove shaft key (7).

• Remove the allen screws in the bearing

cover (81).

• Loosen and remove the bearing cover (81)

with two allen screws (M8) together with the

seal (83) and shaft sealing (82).

• Remove the spacer ring (79).

• Press the drive shaft (72) with bearing (26) and

gear shaft (74) with bearing (26) out of the intermedi-

ate housing in the drive direction, using a sleeve on the

outer bearing ring.

• Pull off and change ball bearings (26).

• The assembly is in the reverse order.

• Please note the following:

- Before pressing on bearing (26) their inner ring should be warmed to 100°C.

- When fitting the bearing cover (81) with the shaft seals (82) an assembly sleeve type II (W

2

)

should be used.

9. Other repairs

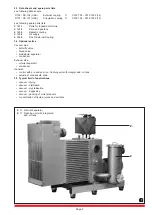

9.1 Cleaning the Suction and Exhaust Ports in Connection Housing (fig. 34)

• Switch off pump and bleed to atmospheric pressure.

• Remove the pipe work.

• Remove the separator (Z).

• Remove the flange (103) from the suction channel (Y

65

) (note seals (104)).

• Remove the hemispherical mesh (118) and clean (solvent).

• Both port areas (Y

65

and Y

66

) can be cleaned through the openings in

the intermediate housing (89). (Please take care, that no dirt enters

the pump).

• Assembly is in the reverse order.

9.2 Changing the Pressure Relief Valve (fig. 34)

• Remove allen screws in the valve (400).

• Carefully remove the valve (400) straight from the

intermediate housing.

• Check all parts and the valve seat in the connection

housing (89). If necessary, regrind the valve seat.

• Before re-assembly check that the valve (404) slides

easily in the valve sleeve (401).

• Assembly is in the reverse order.

10 Instructions for storing fresh oil lubricated rotary vane vacuum pumps

Introduction

Start-up of all pumps delivered by Rietschle should be made within 3 months. If this is not possible, please observe the

following details, the guarantee given by Rietschle may be invalidated if not followed.

a. Storing of pumps

The store room for the pumps must be dry and free of all corrosive materials. The ambient temperature should be constant

and above 10°C.

b. Condition of Stored Pumps

The suction and discharge ports of the pumps should be sealed with blank flanges. All lubricating and sealing oil reservoirs

should be filled, in accordance with the instruction manual.

c. Maintenance during Storage

The pumps should be operated once a month for about 2 hours to prevent any kind of corrosion within the pump. Please

pay attention to the fact, that the blank flange from the discharge side is to be removed before operation and installed again

afterwards. The blank flange of the suction side should not be removed, since end vacuum should be reached.

d. Setting Pumps into Operation

A technical service made by Rietschle will be necessary for all pumps stored longer than 3 months. You will be responsible

for the costs of the inspection and test run. Further, all costs occurring from improper storage or handling will be charged.

/ PM6

9.99