20017376

18

GB

Appendix - Control-box CM222

The Combustion Manager used, is CM222 produced by Krom-

schroeder.

is a microprocessor-controlled gas burner safety control system

designed for use with forced draught modulating gas burners.

OPERATION

The three potentiometers Fig. 15 allow to adjust the speed value

inside the range set in the internal CM222 parameters.

The maximum potentiometer allows to set the maximum speed

and therefore the maximum burnt output, the minimum potenti-

ometer allows to set the minimum speed and the start potentiom-

eter allows to adjust the ignition output.

The display has different functions: it verifies the fan operation,

the failure type and also the function of burner reset button.

ERROR CODE

If the burner control is in lockout the error code is shown in the

display as a blinking number.

The following error codes will be displayed as a blinking number

:

PROGRAM STEPS

B

Appendix - Control-box CM222

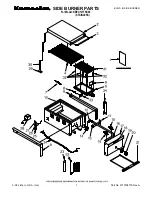

Fig. 15

D9716

Potenziometer max

Potenziometer start

Display and reset button

Potenziometer di minimum

No

.

Error code

Explanation

Buner off

Lockout

1

Failure fan

Fan speed check. Deviation too high

x

x

2

Gas pressure switch

No signal from the gas pressure switch

x

-

3

Failure flame

No flame signal after burner start-up /Flame loss

during burner operation /Flame signal without

burner operation

x

x

4

Failure BCC

Wrong BCC connected /

BCC lost /

BCC parameter block is not valid

x

x

5.0

Failure Remote Reset

More than 5 remote resets in 15 minutes / Perma-

nent remote reset (> 10 sec)

x

/ -

x

/ -

6

Failure gas valve circuit

Gas valve V1/V2 leak

x

x

7

Air prssure switch

No signal from the air pressure switch

x

x

8

Failure CRC

The parameter block is not valid

x

x

9

Failure power supply

The power supply is not sufficient (lower than

185VAC or higher than 270VAC).

x

-

E

Safety shut down

The safety operating system has done a safety

shut down.

x

x

No

.

Program step

Explanation

0

Standby

Waiting for heat demand;

All actors off

1

Standstill check

Fan standstill check; APS-Off-Check

2

Prepurge

Fan speed check; APS-On-Check

3

Prepurge

Fan: prepurge speed; Time is parameter

4

Waiting for ignition speed

Waiting until fan reached ignition speed

5.0

Safety time

Ignition and gas valves on; Fan: ignition speed; Time is parameter

6

Flame stabilization time

Fan: ignition speed for flame stabilization; Time is parameter

7

Burner operation

Fan: Modulation speed

8

Gas valve circuit V1/V2 check

Checking gas valves tightness with flame signal

9

Postpurge

Fan: postpurge speed; Time is parameter