20068118

38

GB

Start-up, calibration and operation of the burner

6.7.0.1 Procedure for inserting and adjusting points on

the modulation curve

Nine adjustment/calibration points (P1 ÷ P9) can be inserted in

the control box for each servomotor, varying their position by de-

grees and, consequently, the quantity of air and fuel introduced.

The

ignition point P0

is independent of the minimum modulation

value. This means that, in the event of difficulty, it is possible to

switch on the burner at a value other than the modulation mini-

mum (

P1

).

To access the

Parameter mode

(group 400) referring to the

To insert or adjust a point, proceed as follows.

Using the keys

“+”

and

“-”

insert/select the curve point you want

and wait for it to flash: this means that the servomotors are now

positioned on the values shown on the display and which corre-

spond to the point previously set.

It is now possible to insert/modify the position by degrees.

For the fuel servomotor, keep the key

“F”

pressed (the position

in degrees flashes) and press the keys

“+”

or

“-”

to increase or

decrease the value.

For the air servomotor, keep the key

“A”

pressed (the position in

degrees flashes) and press the keys

“+”

or

“-”

to increase or de-

crease the value.

To adjust the speed of the inverter (expressed in

%

and that is

50

Hz = 100 %

), keep the buttons

“F”

and

“A”

simultaneously

pressed, the percentage position blinks and press buttons

“+”

or

“-”

to increase or decrease the value.

Select another point, or exit this area by pressing the keys

“+”

and

“-”

(

ESC

) simultaneously.

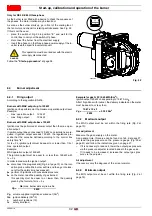

6.7.0.2 CALC function

The diagram (Fig. 36) shows how the fuel modulation curve is

modified if the values of point “

P5

” are changed.

By keeping the

“+”

key pressed for more than 3s, the points

from “

P6

” to “

P8

” are recalculated.

By keeping the

“-”

key pressed for more than 3s, the points from

“

P4

” to “

P2

” are recalculated.

The diagram of (Fig. 37) shows the fuel modulation curve when,

after the modification of point “

P5

”, the recalculation of all the oth-

er points is not carried out.

WARNING

The set value does not require confirmation.

D

9032

P

min

h

s

%

V

D

9033

P

s

%

F

D

9034

P

V

min

h

A

D

12135

h min

%

P

V

VSD

A

F

ESC

Fig. 36

P0

P1

P2

P3

P4

P5

P6

P7

P8

P9

0

10

20

30

40

50

60

70

80

90

100

An

gle (degrees)

Point of the curve

original

curve

CALC-

CALC+

D7908

Recalculation

Fu

el

Fig. 37

P0

P1

P2

P3

P4

P5

P6

P7

P8

P9

0

10

20

30

40

50

60

70

80

90

100

Point of the curve

Angle (degre

e

s

)

D7909

Fu

el

Содержание RS 25/E BLU Series

Страница 2: ...Translation of the original instructions...

Страница 65: ...63 20068118 GB Appendix Electrical panel layout RS 25 E BLU...

Страница 66: ...20068118 64 GB Appendix Electrical panel layout RS 35 E BLU...

Страница 67: ...65 20068118 GB Appendix Electrical panel layout RS 35 E BLU 3Ph...

Страница 68: ...20068118 66 GB Appendix Electrical panel layout RS 25 35 E BLU...

Страница 69: ...67 20068118 GB Appendix Electrical panel layout RS 35 E BLU 3Ph...

Страница 70: ...20068118 68 GB Appendix Electrical panel layout...

Страница 71: ...69 20068118 GB Appendix Electrical panel layout...

Страница 72: ...20068118 70 GB Appendix Electrical panel layout...

Страница 73: ...71 20068118 GB Appendix Electrical panel layout...

Страница 75: ......