10 – English

pressing the Select Key.

Video and Autolog video can be recorded simultaneously

and independently of each other. Both recording types can

be started and stopped without affecting the other.

Recording Autolog Video

Autolog videos are made up of continuous audio recording

and variable frame rate compressed video. The video com-

pression rate of Autolog is approximately one tenth the size

of traditional video recording.

When the camera detects motion, Autolog records stan-

dard frame rate capture at five frames per second. When

the camera does not detect motion, Autolog records one

frame every four seconds. The substantial decrease in file

size compared to traditional video recording, makes storage

and transfer of files easier and less expensive.

While recording an Autolog video, the audio is recorded con-

tinuously, so your narrations are intact and uninterrupted.

Press the Autolog Key to start and stop recording. Press

the Photo Key or the Video Key to capture additional

photos or video while recording an Autolog video. Press the

Select Key to pause and resume Autolog video recording.

Use the Autolog Key to power on and automatically begin

Autolog video recording. Starting the CS6 with the Autolog

Key gives you full documentation of your pipe inspection.

Recording Audio

By default the CS6 records audio continuously during both

Autolog and video recording. Press the Microphone Mute

Key

to toggle audio recording on and off. During play-

back, press the Up or Down Arrow Keys

to increase

and decrease the volume of the recorded audio.

When recording is paused, audio is also paused. To resume

recording, press the Select Key.

Taking Photos

Press the Photo Key to take a photo. The photo icon ap-

pears on the screen briefly and the photo is automatically

saved onto the USB drive in the Active Job.

Measuring the Inspection

The Zero Key can be used in two ways. Press and hold

to set the system zero point at the beginning of an inspec-

tion. A quick press will set a temporary zero point that can

be used to measure a segment of the pipe during an in-

spection.

When a temporary zero point is set the measurement ap-

pears in brackets. Press the Zero Key again to clear the

temporary measurement and return to the system count.

Locating the Camera Using the Sonde

Press the Sonde Key to toggle the Sonde on and off. You

may see interference lines on the screen caused by the 512

Hz signal when the Sonde is on. The lines disappear when

the Sonde is off and are not visible in captured media.

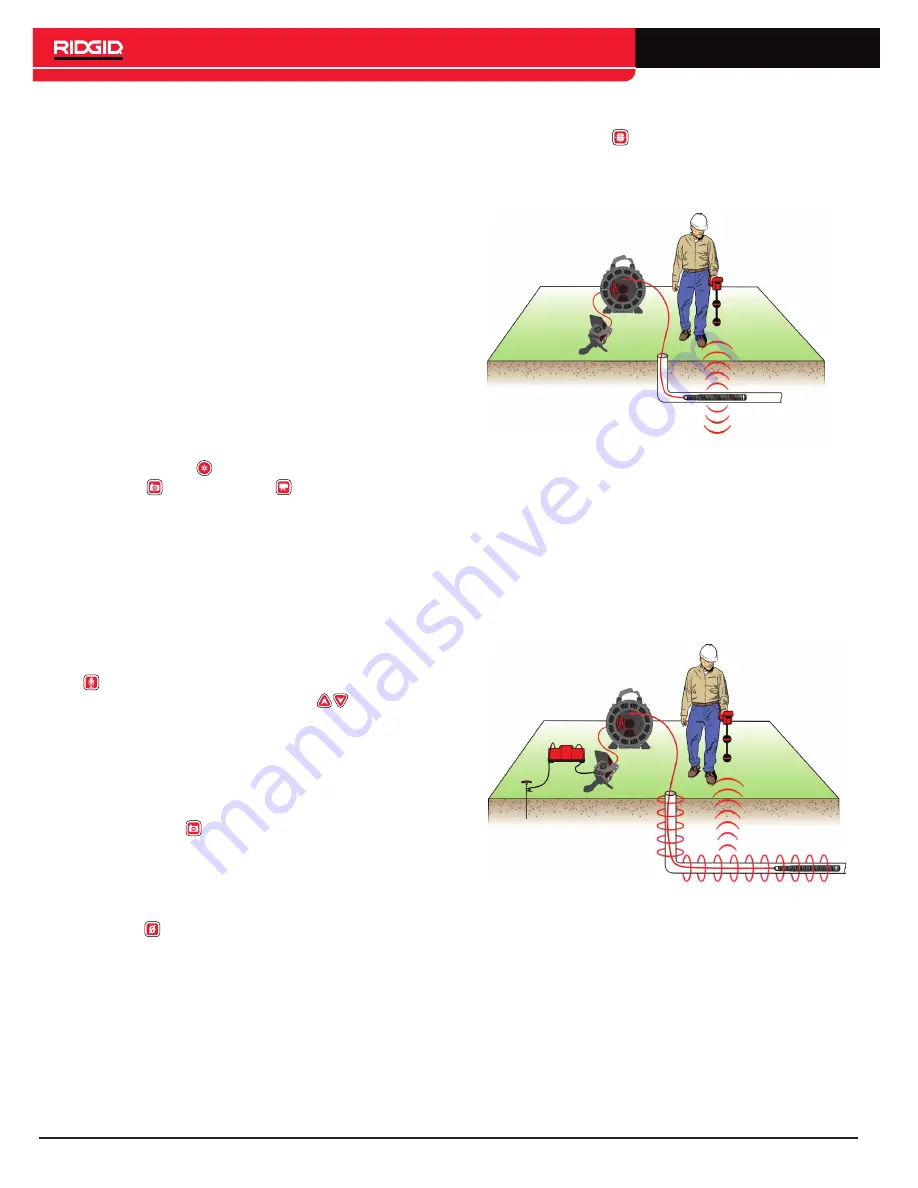

Figure 7 – Locating the Sonde

For detailed instructions on Sonde locating, consult the op-

erator’s manual for the receiver model you are using.

Line Tracing the SeeSnake Push Cable

Line trace to locate the pipe and sonde by inducing current

onto the push cable. To line trace the push cable, clip one of

the transmitter’s leads to the grounding stake and the other

to the Transmitter Clip-on Terminal on the back of the CS6.

Figure 8 – Line Tracing the Push Cable

For detailed instructions on line tracing, consult the operator’s

manual for the transmitter and receiver models you are using.

Содержание SeeSnake CS6

Страница 15: ...English 15 Notes ...