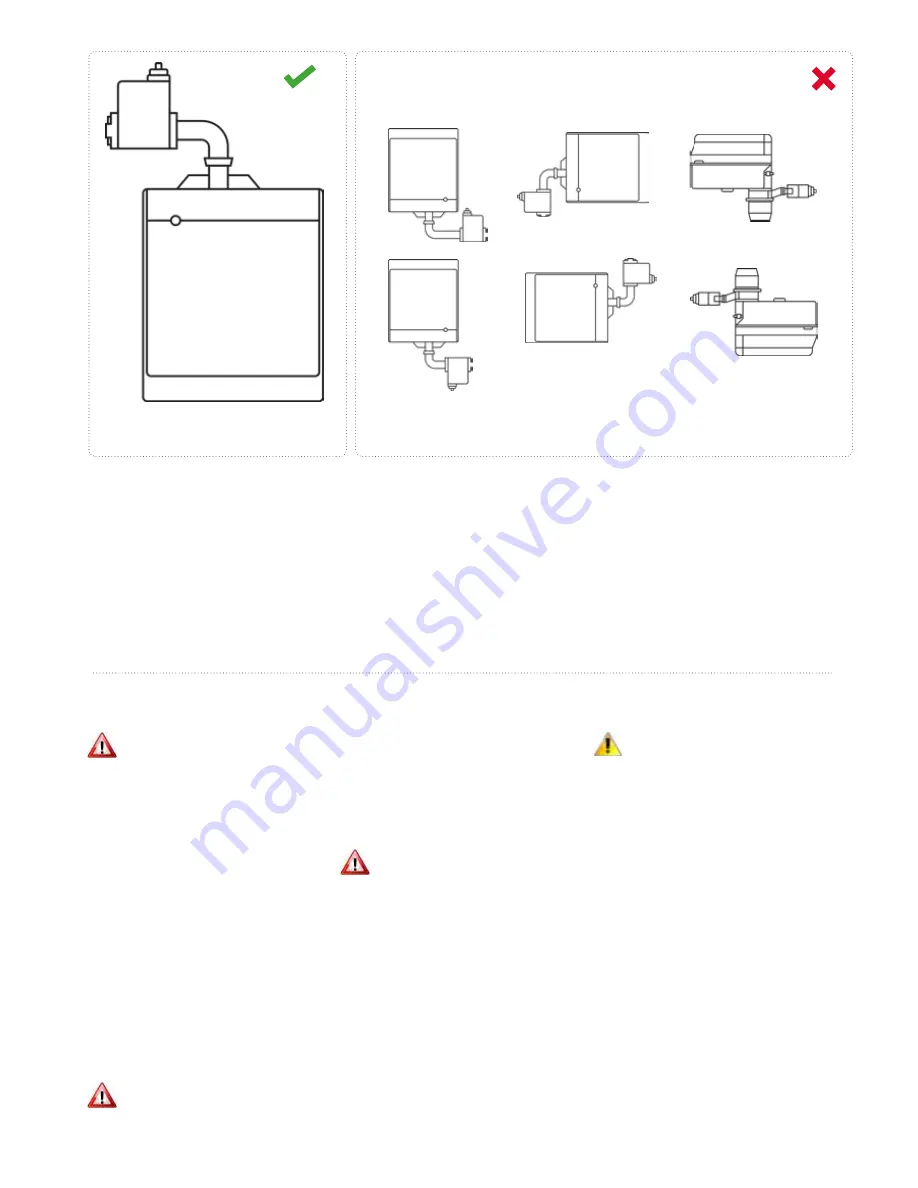

2.9 Burner position

The burner must conform to the local stand-

ards and legislations in place.

The RIELLO-burner has been designed to

operate in the position shown in Figure

11, the positions shown in Figure 12, won't

allow the air damper to close when the

burner is on standby.

Figure 11.

Correct burner position

Figure 12.

Incorrect burner position

2.10 Gas Installation/connection

WARNING

The installation must be purged and tested

for soundness prior to commissioning.

Always ensure that appropriate personal

protective equipment is used

Service pipework must terminate at an

approved isolating valve, and be adjacent

to the position of the heater. The connec-

tion to the heater can be made by way of

either an approved flexible coupling, or

rigid connection. Threaded connections

must comply with ISO288/1 of ISO 7/1,

further information concerning the accepted

practice in European countries is detailed

in EN 1020.

The diameter of the pipework from the

isolating valve to the burner connection

must not be less than the diameter of the

burner connection inlet.

2.11 Oil Installation/connection

WARNING

Prolonged exposure and contact with gas

oil can result in the natural oils being

removed from the skin, sensitisation can result in

dermatitis.

Always ensure that the appropriate personal

protective equipment is used.

2.12 Fuel supply

WARNING

Galvanised or plastic pipe work and fittings

must not be used. (See BS 5410 Part 1)

The constraints of the application will, to a

large extent, determine whether it is prefer-

able to use a single pipe gravity feed system,

or whether the two pipe pumped system is

more appropriate. Where more than one

appliance is to share a common supply it

will be necessary to use a pressurised ring

main system.

All pipe work must be constructed and

installed so that it does not permit the

ingress of air. The construction, size, and

position of the oil storage tank must take

account of the current regulations, as well as

suiting the requirements of the installation.

CAUTION

On pumped systems always check that the

pump is correctly set up prior to operation.

Ensure that valves are open allowing a

free flow of oil through the system.

In order to promote trouble free operating it

is necessary that the oil within the storage

tank and oil line does not fall below the

cold filter plugging point (cfpp), in the UK

and with class D fuel (also referred to as gas

oil). The critical temperature is -4°C for this

summer grade.

The cfpp critical temperature for the winter

grade is -12°C. If summer grade fuel is stored

for winter use in areas prone to severe frosts

and low temperatures it will be necessary

to insulate or even heat the supply tank and

pipe work.

Note:

The fuel supplier should be contacted prior to

installation so that any requirements concerning delivery,

transport, storage and use can be addressed before work

commences.

14