3

Reverso Pumps, Inc. www.reversopumps.com | [email protected] | Ph: (954) 522-0882

Description

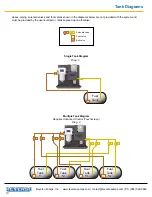

System Description

Reverso Automatic Fuel Polishing (AFP) System is

designed for middle distillate fuels with flash points

of 100°F and above. This includes #1,2 and 3 diesel

fuel, home heating oil and bio-diesel up to B20, with no

modifications required. The AFP single-tank system is

designed specifically to maintain diesel fuel quality in

storage tanks and standby generator sub-base tanks.

This is accomplished by first removing all free water

and particulate to 30 micron in the primary fuel water

separator by Separ Filter, and further reducing particulate

to as low as 2 micron through a secondary filter. This

system is constructed with a 7-day programmable digital

timer, with alarms for high vacuum and high water in the

primary filter, and high pressure in the secondary filter. A

drip pan high level float alarm is also included. Enclosure

is NEMA 3 rated for outdoor installations.

Control

The AFP system operates at 120 volt 60Hz. This system

is equipped with an IDEC PLC control for unattended

operation and is UL508 listed. All system controls are

housed in a NEMA 4 water-tight control box.

Digital control with 7 day programming provides flexibility

in scheduling polishing operations. User can create a

weekly schedule to automaticallly run the system.

The following monitoring systems are provided:

Primary filter high vacuum

Primary filter high water

Secondary filter high pressure

Drip tray high level

When equipped with an enclosure option, an electrical

junction box is located on the exterior and houses the

emergency stop button.

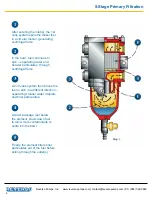

Primary Filtration

The Reverso AFP-600 is designed around the Separ

Filter brand of diesel fuel water separators. This filter

has been specifically designed to utilize hydrodynamic

principles to remove free water and particulate from the

flow of the fuel. By changing the direction of flow and

the velocity of the fuel multiple times, and imparting

centrifugal force, the heavier particulate and free water

drop from suspension and fall to the bottom of the bowl.

As these natural laws are put into effect on the fuel, it

passes through 5 stages within the Separ Filter housing.

For this reason, approximately 70+% of the contaminants

are removed from the fuel prior to passing through

the final stage filter element, bringing the particulate

removal efficiency to 100% for particulate larger than the

element rating (30 micron standard) and a high level

of separation for smaller particulate in test fluid using

standard test methods. At the rated flow of 10 gallons

per minute, the filter is 100% efficient at removing

free water as certified by the RWTUV testing facility in

Germany (copy available upon request).

The 5 stages of separation and filtration are:

Refer to Diag. 1

1. After entering the inlet(s), the 1st vane system

spins the diesel fuel in a circular motion,

generating centrifugal force.

2. In the bowl, fuel continues to spin – separating

water and heavier particulates, through centrifugal

force.

3. A 2nd vane system then forces the fuel ti spin in

a different direction – separating smaller water

droplets and finer particulates.

4. A wider passage, just below the element, slows

down fuel to allow more contaminants to settle into

the bowl.

5. Finally, the element filters finer particulates out of

the fuel before exiting through the outlet(s).

Secondary Filtration

Once fuel has been filtered, it passes through the

pump and finally to a 2 micron filter. It removes

particulate contaminant such as dirt, dust and rust. The

cellulose/microglass media offers higher efficiencies

and longer filter life. Gaskets are pre-lubed. It is

recognized by the Underwriters Laboratory (UL®) for

use with service station pumps and dispensers.

Optional Features

Certain applications can benefit from optional features,

which are additional to the standard AFP System.

Contact your representative for details and pricing.

• Enclosure

• Enclosure for cold climate

• Stand for enclosure

• Magnetic fuel conditioner

• Flow meter

• Automatic Water Drain System for primary filter

• Basic touchscreen control panel

• Advanced touchscreen control: Includes

integration with Building Management Systems

(BMS)