6

REMKO ETF 320

Safety notes

Condensation heat

The Energy transferred to the air

from the condenser consists of:

1. The amount of heat derived

beforehand in the evaporator.

2. The electrical drive energy.

3. The condensation heat released

by liquefying the water vapour.

Energy must be supplied when

liquid is converted into a gas.

This energy is designated as

evaporation heat. It does not

cause any increase in temperature,

but is required to convert a liquid

into a gas. Conversely, energy is

released when gas is liquefied,

this is designated as condensation

heat.

The amount of energy from

evaporation heat and condensation

heat is the same.

For water, this is:

2250 kJ/kg (4.18 kJ = 1kcal)

From this it is evident that the

condensation of water vapour

causes a large quantity of energy

to be released.

If the moisture that it is to be

condensed is not introduced by

evaporation in the room itself,

but from outside, e.g. through

ventilation, the condensation

heat released contributes to

the heating of the room. With

drying operations, a heat cycle

is created, whereby heat is

consumed for evaporation

and released for condensation.

When dehumidifying fed air,

a larger contribution of heat is

created, which manifests itself as

a temperature increase.

Generally speaking, the time

required for the drying process is

not only dependent on the output

of the unit, but is determined to

a greater extent by the speed at

which the material or building

section loses its moisture.

The units have been subjected to

extensive material, functional and

quality inspections prior to delivery.

However, dangers can result

from the units if they are used

improperly or not as intended by

untrained personnel.

The following notes

must be observed in full:

■

The units may not be installed

or operated in explosive

environments

■

The units must not be installed

or operated in atmospheres

containing oil, sulphur, chlorine

or salt

■

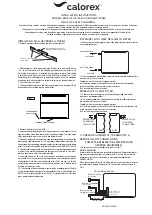

The units must be installed

upright and in a stable position

■

The units must not be exposed

to direct jets of water

■

An unobstructed air inlet and

air outlet must be guaranteed

at all times

■

The air-inlet grille must always

be kept free of dirt and loose

objects

■

The units must not be covered

during operation

■

Never stick foreign objects into

the units

■

The units must not be

transported while they are

running

■

The units may only be

transported upright

■

All electrical cables on the

outside of the units must be

protected against damage

(e.g. by animals etc.)

■

Before each change of location,

the condensate container must

be emptied

Extensions to the connection

cable must only be conducted

by authorised specialist

electricians, taking into

consideration the unit power

consumption, cable length and

local use.

Work on the refrigerant

system and on the electrical

equipment must only be

conducted by a specially-

authorised specialist!

!

CAUTION

!

CAUTION

Содержание ETF 320

Страница 1: ...Edition GB I03 REMKO ETF 320 Mobile dehumidifiers Operation Technology Spare parts...

Страница 2: ......