16

Commissioning of the

Forced-Air Oil Burner

Required nozzle sizes

Selecting the required oil nozzle depends on the pump

pressure and the unit capacity. You may only use an oil

nozzle that is suitable for the shape of the respective

burner chamber with corresponding spray angle, cone

properties, and throughput. You can find the necessary

nozzle size in the technical data.

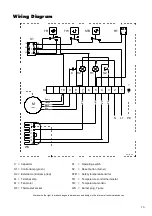

A

A

1

Mount the baffle plate (D) in such a way that the hole

(E) is flush with the photo cell.

Preparation

Before starting with the adjustment of the forced-air oil

burner, perform the following tasks:

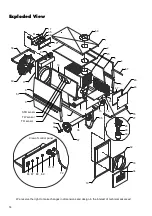

1. Remove the cover of the burner compartment.

2. Remove the fuel line from the burner and pull the

burner plug.

3. Unscrew the four quick-release fasteners of the

mounting base plate (1) at Position A.

The forced-air oil burner may be commissioned

only by expert personnel!

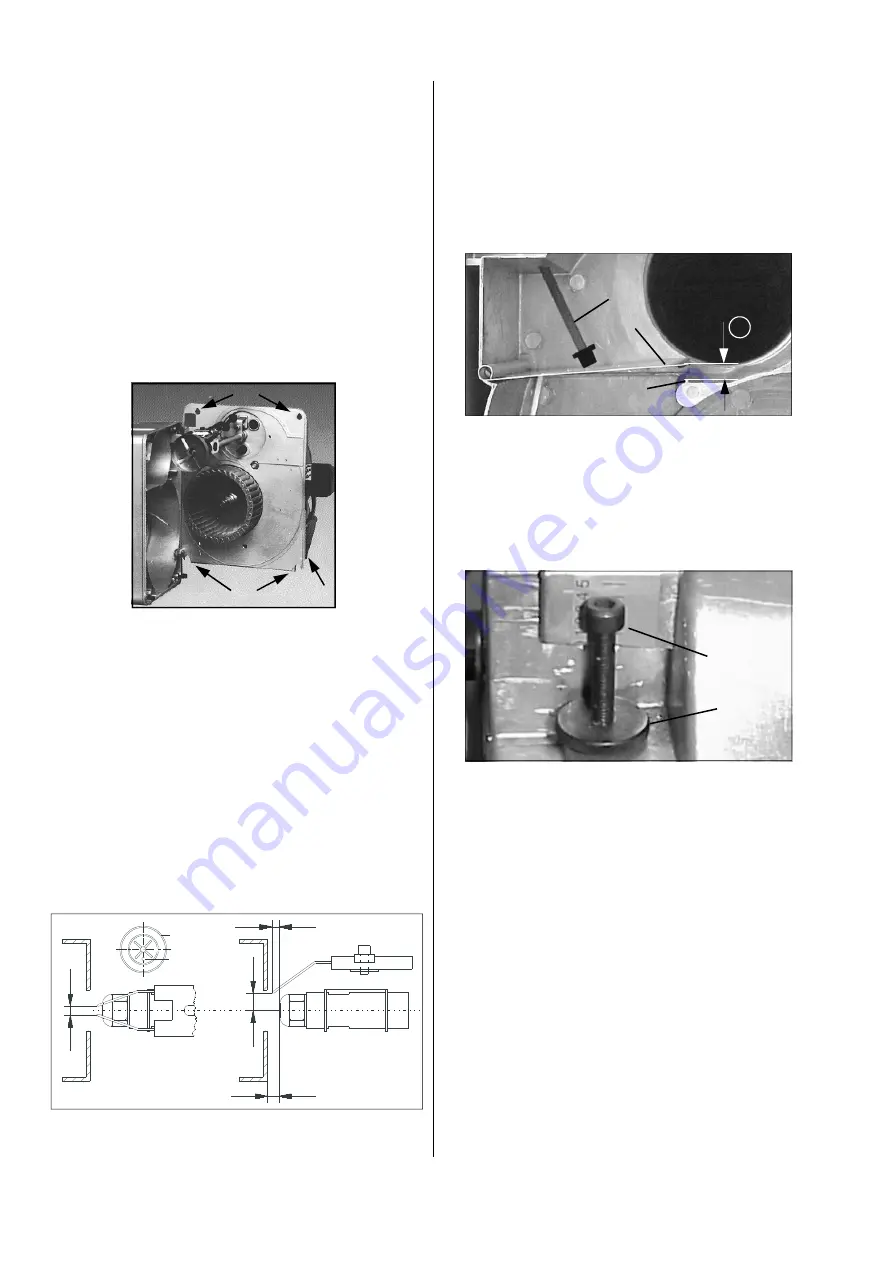

Setting the ignition electrode and baffle plate

All dimensions are approx. values

in mm.

D

E

4

5

4

3

Mounting base plate

After the ignition electrode, baffle plate, and air inlet

nozzle are adjusted, the mounting base plate is re-

mounted.

1. Attach the mounting base plate using the four

quick-release fasteners.

2. Mount the fuel line to the burner.

3. Reinsert the burner plug.

Adjusting the air flap

Adjust the air flap using the adjusting screw (7) in such a

way that Distance A between the air flap (8) and the stop

(9) amounts to approx. 6 mm.

To adjust the necessary distance, proceed as follows:

1. Loosen the knurled nut (10) and turn the adjusting

screw (7) accordingly.

Clockwise rotation:

Distance A becomes smaller

Counterclockwise rotation:

Distance A becomes

larger

A

7

8

9

10

7

2. After adjusting the distance, retighten the adjusting

screw using the knurled nut (10).

The optimum setting must be adapted to the lo-

cal conditions and the respective chimney.

4. Carefully remove the complete mounting base plate

from the front of the unit.

5. Place the mounting base plate somewhere suitable

for the further tasks.

D

Содержание CLK 20

Страница 2: ......