4

Air Handling Units

Despatch

Side Variability of Unit Connections

Connection side is always determined by the air-flow

direction:

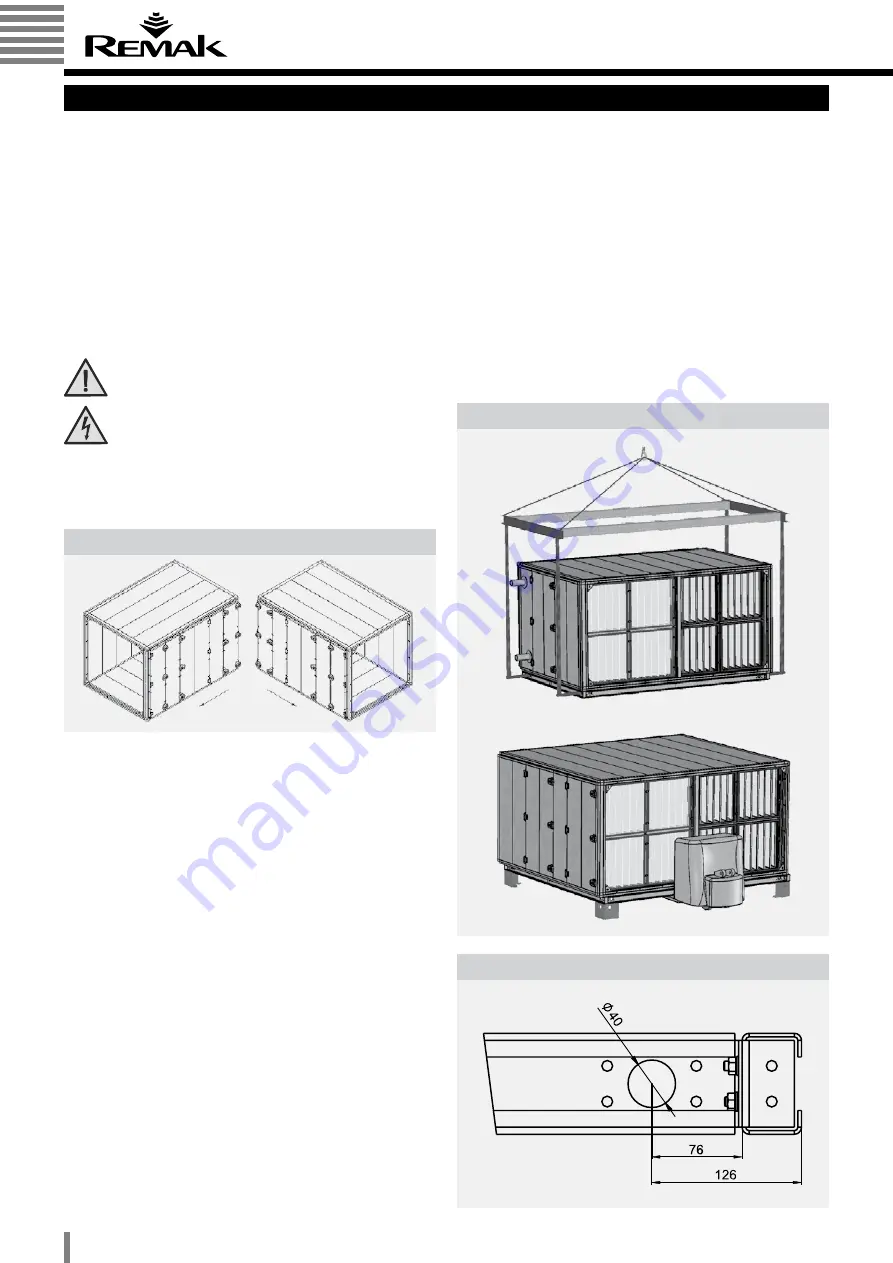

Transport and Handling of Components

Air-handling units are transported to the installation site

either as transport-installation blocks or disassembled (for

transport and handling of disassembled units, refer to the

separate manual).

Loading, unloading and handling can be performed by a

fork-lift truck, a manipulating carriage or a crane. If lifted

by crane, spacer bars must be inserted between the lifting

wires to protect the air-handling unit from being damaged.

If air-handling unit blocks without a base frame are han-

dled, fork-lift truck forks of a sufficient length must be

used to overreach the full depth of the lifted block. If the

air-handling unit block with a base frame is handled, forks

of a sufficient length must be used to overreach both side

beams of the base frame.

Figure 2 –

Handling options

The "Other Danger" warning label situated on the face

side of the service door indicates the hazard of catching

by movable parts.

The service panels covering electrical equipment are

labelled with a "Warning – Danger of Electric Shock"

warning label.

Information and safety labels

AeroMaster CIRRUS air-handling units, respectively indi-

vidual sections, are also labelled with information labels

indicating equipment operation, wiring diagrams, energy

media inlets and outlets and logos of the manufacturer.

Delivery Contents

The following items are enclosed with every delivery of

the air-handling unit:

Accompanying technical documentation

(Installation and Operating Instructions)

Commercial and technical documentation, including

air-handling unit assembly drawing

Connecting material kit

Installation kit

Measuring & control components, respectively

accessories in accordance with the bill of delivery

Transport and Storage

Air-handling units with a base frame of standard height

(85mm) are dispatched on a pallet or transportation

prisms.

Air-handling units equipped with a raised base frame

(with supporting legs) are dispatched without additional

handling means.

Packaging

As standard, the transport blocks of the Cirrus air-handling

units are packed in PE foil and provided with cardboard

and polystyrene protecting guards. The holes in the base

frame can be used to lift the unit by a crane.

Figure 1 –

side variability of unit connections

LEFT-HAND VERSION

RIGHT-HAND VERSION

Air-flow

direction

Figure 3 –

Handling holes in base frame

Each built-in assembly is marked with a type (name)

plate situated on the service panel side. The name plate

includes the technical parameters of the given built-in as-

sembly. The user must ensure that every marking on the

unit components will be readable and intact for the whole

service life of the unit. If damaged, especially if safety is

concerned, the marking must be repaired immediately.