Controls

Function

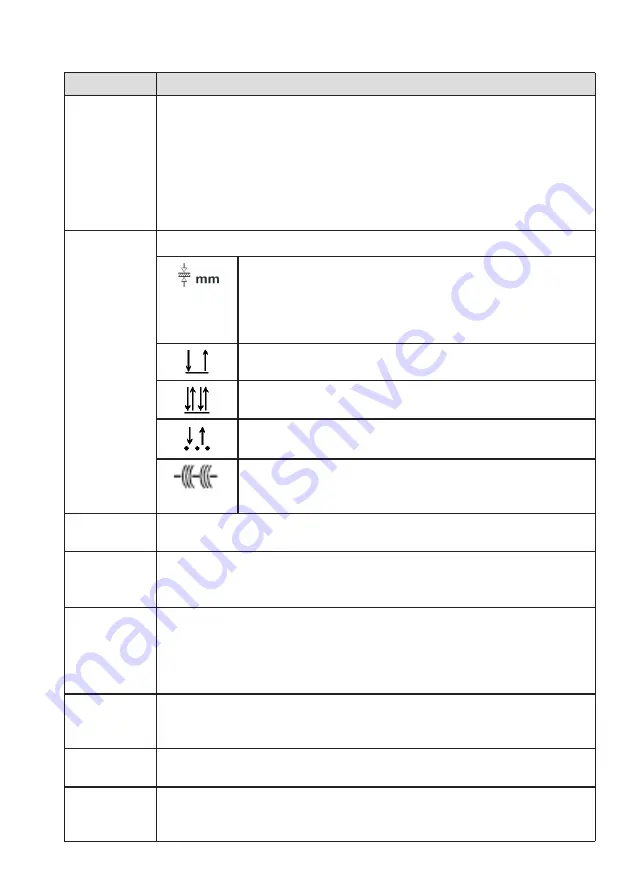

6

Correktion of wire speed

Fine adjustment for wire speed in addition to the machine calculated

speed by adjustments of you did with the rotary cam switches 11 and

12. The correction value stays active even if you change steps.

Negative correction = reduces wire speed => arc gets longer

Positive correction = increases wire speed => arc gets shorter

If arc energie gets too low and welding result isn‘t convinient you

need to change output voltage by the rotary switches.

7

Mode switch

Auxiliary function to find the right adjustment for a

certein material thickness. 7-Segment indicator 2.

For control reason value of calculated material thickness

is show shortly when activating the torch button.

If arc is astablished indicator show welding current.

2-Step mode

4-Step mode

Spot welding - time adjust with potentiometer 8

Pulse welding - Interval welding

Pulse time can be adjusted with regulator 8,

the pause time is half the pulse time.

8

Time setting

for functions spot and pulse welding [0.1 ... 5.0 sec]

9

Material selection switch

Selection of material like aluminium, copper (CuSi3), steel and stain-

less steel (CrNi) and wire thickness like 0.8, 1.0, 1.2 mm

10

SDI adjustment

Stepless adjustable DC choke to allow hard or soft welding arc.

If potentiometer is in the left stop position Automatic SDI is switched

on. Now application controller is calculating adjustment according to

position of rotary switches.

11

Rotary cam switch - coarse adjustment

Not available in all products. Big increase of output voltage and

welding current.

12

Rotary cam switch - fine adjustment

Stepwise increase of voltage and current.

13

FOCUS switch

Arc will be focussed. Available only at products 304, 404 und 504 and

only for steel and stainless steel welding.