Commissioning

Reflexomat XS — 02.16.2022 - Rev. A

English — 21

6.5

Power Supply

DANGER

Risk of serious injury or death due to electric shock.

If live parts are touched, there is risk of life-threatening injuries.

•

Ensure that all phases of the mains power supply to the product are

disconnected prior to installation.

•

Ensure that the system is secured and cannot be reactivated by other

persons.

•

Ensure that installation work for the electric connection of the device is

carried out by an electrician, and in compliance with electrical

engineering regulations.

All electric connections between control unit and expansion vessel are pre-

installed.

1.

Connect the mains plug to the 230 V power supply.

2.

Activate the system.

The electrical connection is completed.

6.5.1

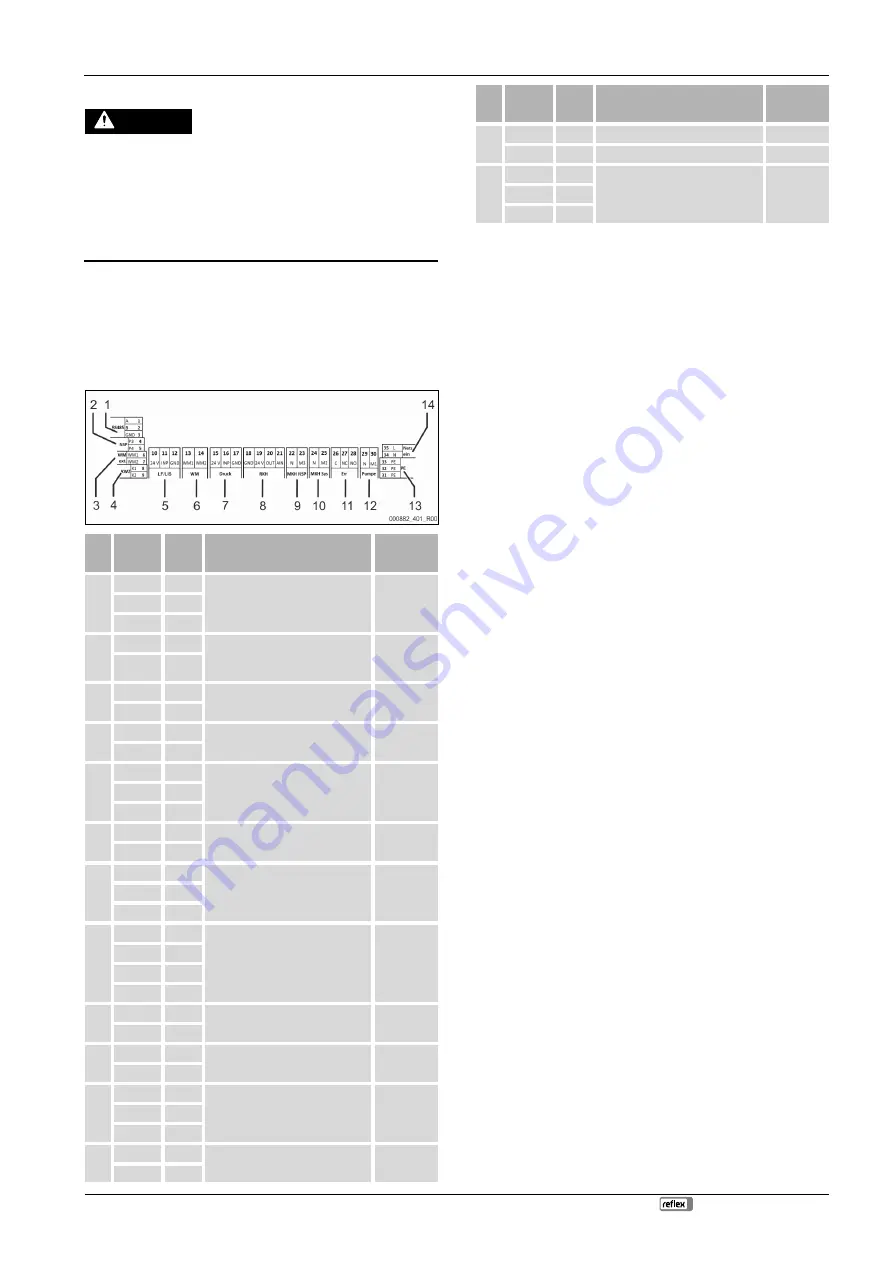

Terminal diagram

Item

no.

Terminal

number

Signal

Function

Wiring

1

1

GND

RS485 interface for Modbus RTU or

proprietary Reflex protocol

On-site,

optional

2

A

3

B

2

4

P3

External make-up request

•

With the Levelcontrol setting.

Input 230 V signal via L+ N

On-site,

optional

5

P4

3

6

WM1

---

---

7

WM2

4

8

K1

Contact water meter

•

Digital input

On-site,

optional

9

K2

5

10

24 V

Filling level measurement

•

Analogue input 4-20 mA

Factory

11

INP

12

GND

6

13

WM1

---

---

14

WM2

7

15

24 V

Pressure sensor

•

Analogue input 4-20 mA

Factory

16

INP

17

GND

8

18

GND

---

---

19

24 V

20

OUT

21

AIN

9

22

N

Make-up request 230 V

On-site,

optional

23

M3

10

24

N

Solenoid valve on the air side

Factory

25

M2

11

26

C

Potential-free group alarm contact

(max. 230 V / 8 A)

On-site,

optional

27

NC

28

NO

12

29

N

Compressor/relief valve

Factory

30

M1

Item

no.

Terminal

number

Signal

Function

Wiring

13

31

PE

Earthing

Factory

32

PE

Earthing

Factory

14

33

PE

230 V voltage supply via cable with

power plug.

Factory

34

N

35

L

6.5.2

RS-485 interface

This interface is used to retrieve all controller data and to enable communication

with control centres or other devices.

The following data can be requested:

•

Pressure and filling level.

•

Compressor operating states.

•

Operating states of make-up via solenoid valve.

•

Aggregate volume of the FQIRA + contact water meter.

•

All messages,

•

All entries in the error memory.

6.5.2.1

Connecting the RS-485 interface

•

Use a shielded cable to connect the interface to terminals 1 – 6 of the

circuit board in the control cabinet.

–

For connecting the interface,

•

When using the device with a control centre not supporting an RS-485

interface (RS-232, for example), you must use a corresponding (on-site)

adapter.

Note!

For connecting the interface use, for example, a cable with these

properties.

•

LIYCY (TP), 4 × 2 × 0.8, maximum overall bus cable length 1000 m.

6.6

Installation and commissioning certificate

Note!

The installation and commissioning certificate can be found at the end

of the operating manual.

7

Commissioning

Note!

Commissioning and maintenance work must be carried out and

confirmed by specialist personnel or the Reflex Customer Service.

Note!

The app guides you through commissioning

7.1

Requirements for initial commissioning

The Reflexomat will be ready for initial commissioning when the tasks described

in the "Installation" chapter have been completed.

•

The Reflexomat has been located.

•

The weight measuring cell is connected.

•

The water-side connection of the vessel to the system circuit has been

established.

•

The vessel is not filled with water.

•

The connection pipes of the Reflexomat have been purged and cleaned of

welding residue and dirt before commissioning.

•

The draining valves of the vessel are open.

•

The entire system has been filled with water and all gases have been

vented in order to ensure circulation throughout the entire system.

•

The electrical connection has been created according to applicable

national and local regulations.

7.2

Reflexomat switching points

The "P

0

" minimum operating pressure is determined by the location of the

pressure maintenance system. The controller calculates the switching points for

the "PV" solenoid valve and the "CO" compressor from the "P

0

" minimum

operating pressure.

Cooke Industries - Phone: +64 9 579 2185 Email: [email protected] Web: www.cookeindustries.co.nz