Operation

22 — English

Reflexomat XS — 02.16.2022 - Rev. A

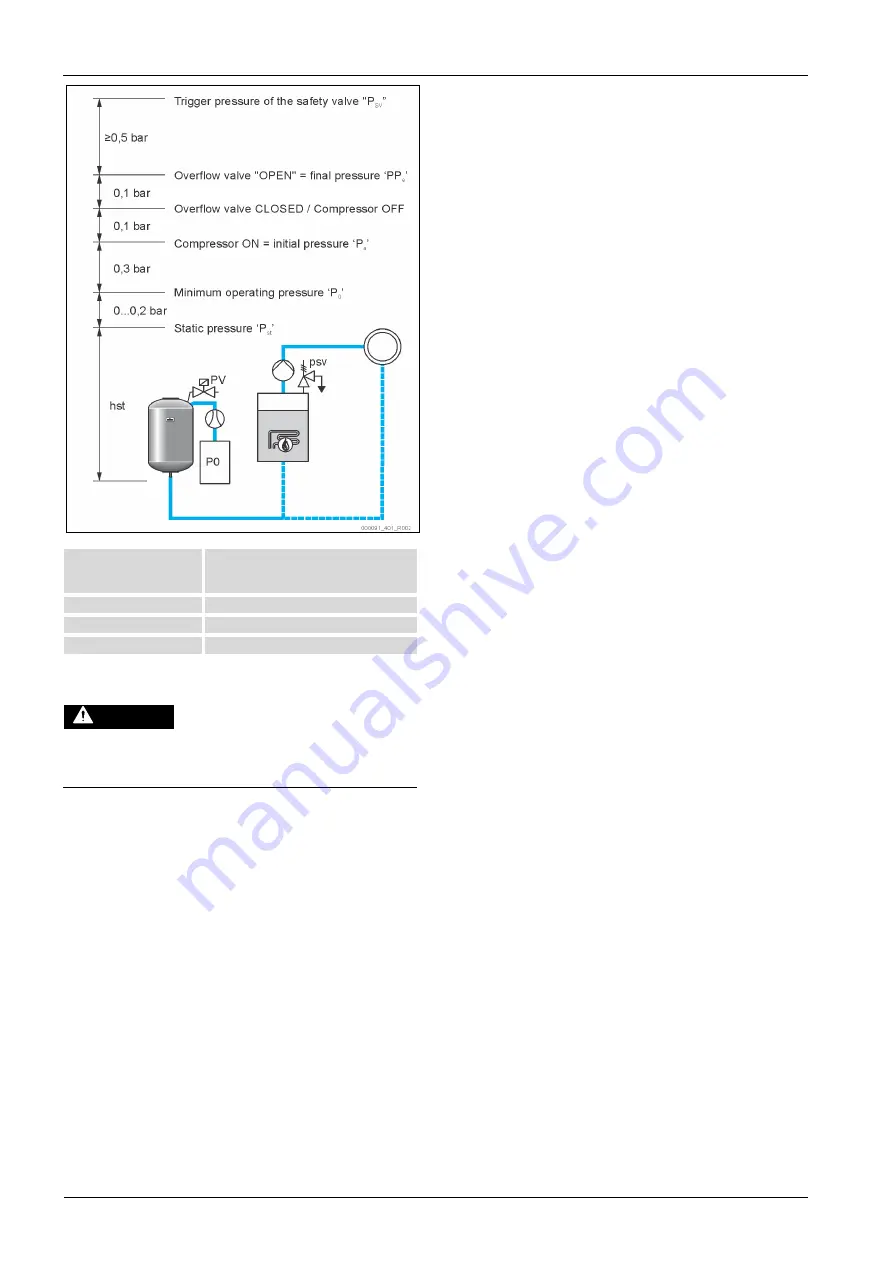

The "P

0

" minimum operating pressure is calculated as follows:

P

0

= P

st

+ P

D

+ 0.2 bar*

Enter the calculated value in the start routine

of the controller,

P

st

= h

st

/10

h

st

in metres

P

D

= 0.0 bar

for safety temperatures ≤ 100 °C

P

D

= 0.5 bar

for safety temperatures = 110 °C

*Addition of 0.2 bar recommended, no addition in extreme cases

7.3

Venting the vessels

CAUTION

Risk of burns on hot surfaces

Excessive surface temperatures on the compressor can result in skin burns.

•

Wear suitable personal protective equipment (safety gloves, for

example).

After setting the minimum operating pressure P

0

in the assisted commissioning

via the app, the primary vessel must be vented. Proceed as follows:

1.

Ensure that the cap valve is closed.

2.

Open the draining valve.

3.

In the app control panel, press on "Start".

The "CO" compressor builds up the pressure required for venting. This pressure is

0.4 bar above the set minimum operating pressure. The vessel’s membrane is

acted on by this pressure and the water side in the vessel is vented. Close the

draining valves of the vessel after the compressor has been automatically shut

down.

Note!

Inspect all compressed air connections between the control unit and the

vessel to ensure their leak tightness. Subsequently, slowly open all cap

valves at the vessel to create the water-side connection to the system

circuit.

7.4

Filling the tanks with water

Prerequisite for fault-free filling is a make-up pressure at least 1.5 bar above the

final pressure "P

e

".

•

Without automatic make-up:

–

Use the draining valves or the system circuit to manually fill the

vessel to approximately 30 % of the vessel volume,

•

With automatic make-up:

–

The vessel is automatically filled to 12% of its volume,

7.5

Starting Automatic mode

Automatic mode can be set after initial commissioning. Start automatic mode at

the control panel of the controller.

The following prerequisites must be met for automatic mode:

•

The device is filled with compressed air and water.

•

All required parameters are defined in the controller.

Press "Auto" for automatic mode on the control panel of the controller.

•

The "Auto" LED on the control panel illuminates to visually signal

automatic mode.

Note!

Initial commissioning is completed and the device is in automatic mode.

8

Operation

8.1

Operating modes

8.1.1

Automatic mode

Use:

After initial commissioning has been successfully completed

Start:

Press "AUTO".

Functions:

•

In automatic mode, the controller monitors the following functions:

–

Maintaining pressure

–

Expansion volume compensation

–

Automatic make-up.

•

The "CO" compressor and the "PV" solenoid valve (optional) are regulated

by the controller so that the pressure remains constant in a regulation

range of ± 0.1 bar.

•

Faults are displayed on the control panel and in the app.

8.1.2

Stop mode

Use:

Stop mode interrupts automatic mode and is a prerequisite for manual mode.

Start:

Press "Stop" on the controller. The Auto LED of the control panel goes out. The

Stop LED lights up in yellow.

Functions:

Function monitoring is not performed in stop mode.

The following functions are deactivated:

•

The "CO" compressor is switched off.

•

The "PV" solenoid valve is closed.

Note!

If stop mode is activated for longer than 4 hours, an error message

appears on the device to signal an uncontrolled deactivation. This is also

indicated in the Reflex Control Smart app.

8.1.3

Manual mode

Use:

For testing and maintenance work

Start:

1.

In the display, switch the system to stop mode.

2.

In the app, switch the system to manual mode.

Setting

Maintenance

Manual mode

3.

Start manual mode.

4.

Select the desired function.

Switch the function on and off by touching the corresponding button:

•

The button is highlighted white. The function is switched off.

Press the desired button:

•

The button is highlighted green. The function is switched on.

Functions:

Manual mode allows you to select the following functions and to perform a test

run:

•

Compressor

•

Solenoid valve

•

Make-up

•

Potential free group fault.

Cooke Industries - Phone: +64 9 579 2185 Email: [email protected] Web: www.cookeindustries.co.nz