Introduction

Congratulations on your purchase of the MAX

®

E-Series upgrade kit to

convert the rear sump of your MAX

®

E-Series complete reef system to an

in-cabinet sump.

This manual covers the installation and operation of the in-cabinet sump

and complements the operation manual provided with your E-Series

aquarium system.

Upgrade Options

•

Piping kit

: Includes flow-regulated main downpipe, a secondary overflow

bypass pipe and return pipes for assembly in the multiport bulkhead.

• Glass Sump

(optional): including Bubble trap sponge, 225 micron filter

bags and Float valve for automatic top-up and RO Reservoir.

• Rear Cover

(optional): An optional rear cover is available to replace the

sump screen. This cover reduces noise from the water fall of the surface

skimmer and will help in reducing evaporation.

Overview of the E-Series water management system

Pipe System

The silent-flow downpipe system includes a flow-regulated main

downpipe and a secondary overflow bypass pipe.

The fine adjustment flow valve on the main downpipe enables the water

level in the rear to be maintained at a constant height between the intakes

of the main and bypass pipes, which ensures positive surface skimming

while eliminating all noise from the water flow to the sump. An incorrect

setting of the flow valve will be accompanied by the sound of the water

returning to the sump and is an indication that the flow valve needs

adjusting.

The multidirectional eyeball outlet on the return pipe is easily

disassembled for maintenance.

Sump /ATO (optional)

Water from the flow-regulated main downpipe and the secondary

overflow bypass pipe enter a compact reception chamber in the sump that

is also suitable for housing chemical media such as carbon.

The water then flows through the 225 micron filter before entering the

constant-height main reactor or skimmer chamber. If the filter bags are

not cleaned frequently enough and become blocked, the water will bypass

the filter bags without affecting the overall operation of the sump.

A bubble trap labyrinth with coarse foam separates the reactor chamber

from the pump compartment to prevent bubbles from the skimmer being

returned to the aquarium.

Any loss of water due to evaporation will cause a drop in the water level

in the pump compartment of the sump which will be compensated by the

ATO system.

Maintaining a constant water height in the pump compartment (with the

ATO) is essential for the stability of the entire water management system

by ensuring a constant head pressure on the intake of the main pump.

The reservoir contains water for approximately 3 days of evaporation and

should be kept topped up at all times.

It is recommended to use a return pump with at flow of at least 2700 lph.

Installation

Before adding the sump to the cabinet it is recommended to seal the join

between the walls and the base of the cabinet with a silicone sealant.

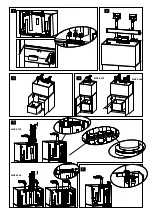

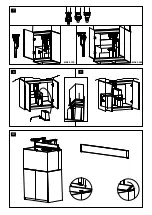

Please refer to the accompanying graphic manual as directed below.

1.

Switch off all of the components at the power center.

2.

Remove the Rear Sump Screen and the grill from the return outlet

port.

3.

Inspect the plugged multiport bulkhead from the cabinet side while

the cabinet is still empty to better understand the construction.

4.

Unplug the skimmer pump and remove the skimmer from the rear

sump.

5.

Make sure that the cabinet doors are correctly aligned (review the

instructions in the cabinet assembly manual). Once the sump is in

position it will not be possible to make adjustments to the lower

hinge without moving the sump. Insert the sump into position in the

cabinet, see the graphic manual for the exact position.

Do not

put the

RO reservoir in position or add any other additional equipment to the

sump until instructed.

6.

Syphon aquarium water

from

the skimmer chamber of the rear sump

down into the empty sump until the

skimmer chamber is dry

and

remove any remaining water with a cloth.

7.

The water in the main tank will drop to between 9cm (3.5”) and

16.5cm (6.5”) below the normal water height. There is more than

enough room in the sump to take all of the water that will drain from

the tank.

8.

Remove the 3 plugs from the multiport bulkhead by either

unscrewing by hand from the top of the tank or by using an open

pair of pliers from the cabinet side. Any residual water in the

skimmer chamber will flow through the open bulkhead.

9.

Thread the 3 top pipes into the multiport bulkhead as shown in the

graphic manual. Make sure that that the O-rings are in position on

the connectors before assembly. To ensure correct assembly, firmly

hold the threaded connectors from inside the cabinet and tighten

well by hand. Do not use tools. Avoid unscrewing the pipes from the

multiport bulkhead once assembled as the locking mechanism that

prevents counter-rotation will be less effective.

10. Insert the return outlet assembly into the outlet port and return pipe

and tighten the securing nut.

11. Connect the main downpipe and secondary overflow bypass pipe

to the connectors of the top pipes as shown in the graphic manual.

Make sure that that the O-rings are in position on the connectors

before assembly.

12. Using the flexible hose provided attach your return pump to the

return pump connector making sure that all joins are secure and if

necessary add a hose clip. Place the return pump into the return

pump chamber in the sump and attach to the connector of the return

pipe.

13. After assembly check that the pipes are vertical and the securing

nut is holding the pipe in position. Do not use tools and do not

overtighten.

14. Check that the outlet nozzles of the return pipe and the circulation

pumps are pointed downwards.

Technical Data

Model

Sump Total

Volume

Sump

Working

Volume

Total System

volume with

Sump

Skimmer

Chamber

Dimensions

MAX

®

E-170

85L – 22gal

41L – 11gal

200L – 53gal

30 x 32cm

11.8" x 12.6"

MAX

®

E-260

95L – 25gal

46L – 12gal

288L – 76gal

35 x 32cm

13.8" x 12.6"

WARNING

: If you are not experienced in the installation of aquarium

systems, seek suitably qualified assistance.

Note

: Before performing the upgrade prepare new seawater according

to the sump working volume (see table above) plus 6% to

compensate for the higher water level in the rear sump.

Red Sea MAX

®

E-Series | In-Cabinet Sump Upgrade Manual

ENG

Содержание Complete Plug & Play MAX E Series

Страница 2: ......

Страница 3: ...Red Sea MAX E Series In Cabinet Sump Upgrade Manual...

Страница 4: ...1 3 4 2 5 6 MAX E 170 MAX E 170 MAX E 260 MAX E 260 30 mm 30 mm...

Страница 5: ...7 8 9 10 MAX E 170 MAX E 260...

Страница 12: ......

Страница 13: ......

Страница 15: ...ATO ATO 1 MSK 900 MSK 900 MSK 900 REEF SPEC 20cm RO 3 24 MAX E CHN...