15. Pour approximately 3 liters of seawater into the skimmer chamber

of the rear sump to ensure that all of the pipe joins are watertight.

Check for leaks inside the cabinet.

16. Remove the black sponge from above the circulation pump/s and

replace the closed grill plugs with the open grill plugs that are

supplied with the pipe kit.

17. Open the main flow valve (rotate anti-clockwise) to maximum.

18. Plug the return pump into one of the auxiliary outlets on the power

center.

19. Place the RO reservoir in position, connect the outlet to the float

valve and fill with RO water but close the flow valve on the outlet of

the reservoir.

20. Install your protein skimmer and any other equipment that will be in

the sump. Please note that at this point the water height in the sump

is still much higher than normal.

21. Add approximately 40 liters (10 gallons) of new seawater to the

aquarium.

22. Switch on the return pump, the circulation pumps and any equipment

you have added to the sump. Add more water as required to

maintain 15cm/6" of water in the return pump compartment.

23. Allow the system to run for a few minutes and adjust the flow valve

(as described below) so that the water level in the rear sump is

between the main downpipe and the overflow bypass and there is

no noise. Add/remove water to/from the system and adjust the flow

valve until the water levels in the system stabilize.

Main downpipe valve adjustment

To raise the water level in the rear sump, rotate the valve clockwise.

To lower the water level in the rear sump, rotate the valve anti-clockwise.

The main downpipe flow valve provides a very fine control of the flow

rate however after making adjustments it takes the system a few

minutes to stabilize at the new setting.

Once you have established the approximate setting for the valve make

very small adjustments and wait for a few minutes each time. It may take

a number of occasional adjustments to reach a stable level. When set

properly this system removes all of the noise of water flowing down to

the sump.

ATO:

On initial set-up, wait until the saltwater system is stable before using the

ATO.

Disconnect the top-up flow valve from the float valve and slowly open the

flow valve until the top-up water drips at a rate of approximately 1 drop

per second. Reconnect the flow valve to the float valve.

Adjust the angle of the float so that the valve is closed when the water

level is above the inlet of the pump but below the top of the bubble trap.

Power-out test:

After completing the upgrade and after adding any new equipment to the

sump, make any adjustments necessary to the main valve to stabilize the

system and perform a “power-out” test to check that water does not rise

above the rim of the sump.

MSK 900 Protein Skimmer:

The MSK900 protein skimmer is designed specifically for a rear sump

application with a high water level.

The MSK900 will operate with full reef spec performance if used inside

the in-cabinet sump however there will be excessive noise due to the

approximately 20cm 8" of height difference between the skimmer outlet

and the water level in the skimmer chamber. Attaching sponge to the side

of the skimmer will effectively cancel the noise.

Maintenance

For continuous smooth operation of the water management system make

regular checks of the following:

Water level in the rear sump - adjust the flow valve as required.

Water level in the reservoir – top up with RO water as required.

Water level in the sump, check that the top-up float valve is operating

correctly.

Micron Filter Bags – check that water is flowing through the bags and

replace as required.

Surface skimmer combs – remove any deposits that reduce water flow.

Pump outlet nozzle – check for blockages and build-up of algae.

Micron Filter bags

It is recommended to have at least 3 sets of filter bags.

There are a few options for cleaning the filter bags:

Quick and effective – Spray the outside of the bags with a powerful water

jet such as a garden hose to back-flush the detritus from the felt.

More thorough – soak the bags in bleach or diluted vinegar for 24 hours

prior to spraying as above. Rinse well to remove all chemicals before

returning to sump.

The filter bags can also be put in a cold wash in a washing machine with

regular detergent or with vinegar (may require approval from a higher

authority).

WARNING

: Overfilling the sump with equipment may cause a

flood in the event of an interruption of electric power.

NOTE

: It is recommended to close the valve on the outlet of the

reservoir whenever doing maintenance in the sump.

Red Sea MAX

®

E-Series | In-Cabinet Sump Upgrade Manual

ENG

Содержание Complete Plug & Play MAX E Series

Страница 2: ......

Страница 3: ...Red Sea MAX E Series In Cabinet Sump Upgrade Manual...

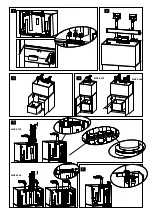

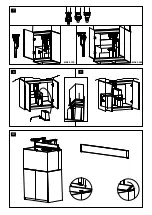

Страница 4: ...1 3 4 2 5 6 MAX E 170 MAX E 170 MAX E 260 MAX E 260 30 mm 30 mm...

Страница 5: ...7 8 9 10 MAX E 170 MAX E 260...

Страница 12: ......

Страница 13: ......

Страница 15: ...ATO ATO 1 MSK 900 MSK 900 MSK 900 REEF SPEC 20cm RO 3 24 MAX E CHN...