Fi

d

b

b il

&

h

B il

M

l

Finned copper tube gas boilers & water heaters – Boiler Manual

25

F

F

CHECKING & ADJUSTMENTS

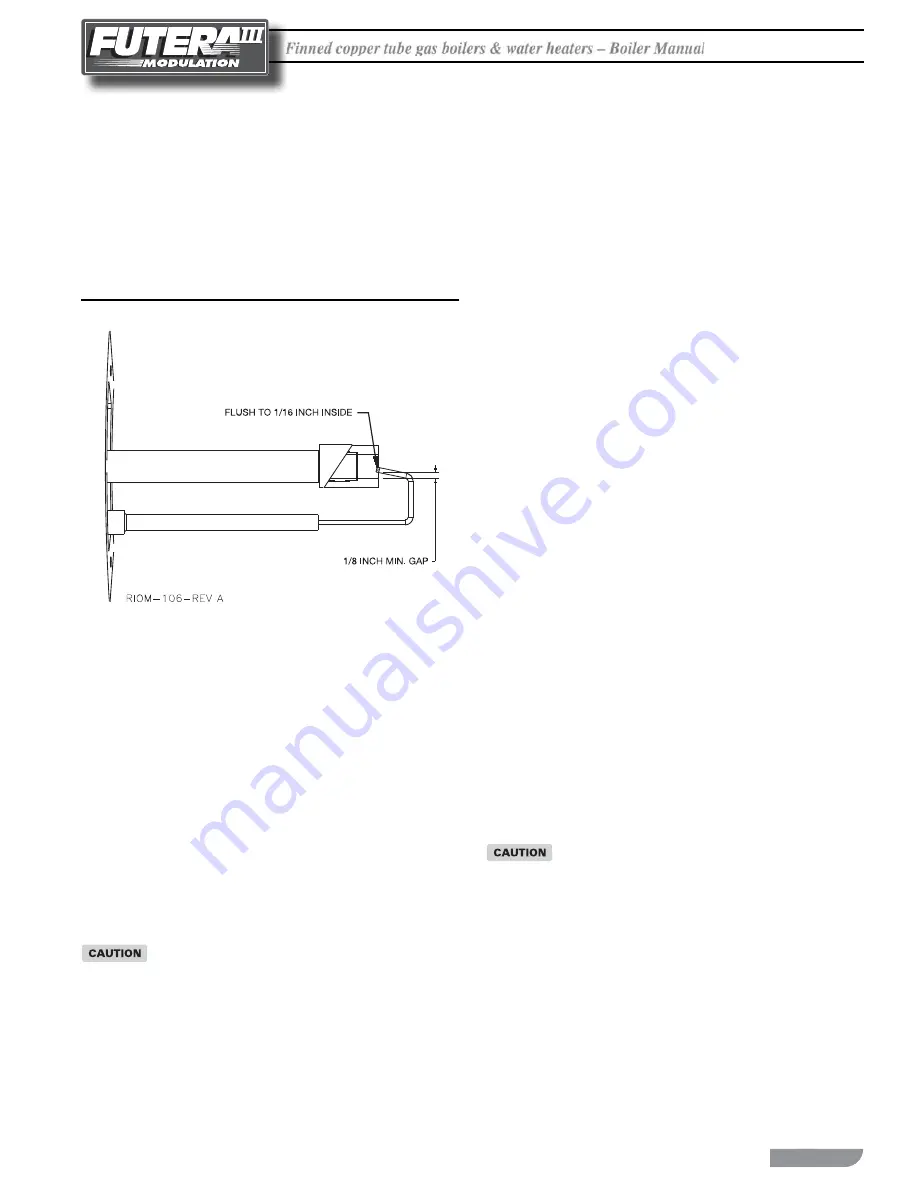

Spark Gap

With the main and pilot gas manual valves in the closed position

energize the unit. Observe the trial for ignition to confi rm that the

spark is strong and continuous. If not check and adjust the spark

gap as shown in Figures 17 &18.

Figure 16

Spark Gap

Pilot Adjustment

Th e pilot pressure has been factory set at 3 in. W.C. for natural and

LP gas and shouldn’t need adjustment. To check the pilot pressure

close the manual main shut-off valve 2 and the pilot gas shut-off

valve, Figure 14. Remove the 1/8" pipe plug from the pilot tee and

connect a manometer having a minimum range of

6 in

,

152 mm

WC to it. Open the pilot gas shut-off valve. With the unit powered,

generate a call for heat. When the prepurge is complete the ignition/

pilot trial will begin. At this point put the Honeywell RM7800 test

switch in the test position. Th e control will hold in the ignition/

pilot sequence allowing you to check the pressure.

To adjust the pilot the following steps must be taken:

1. Remove the pilot gas pressure regulator cap.

2. Turn the pressure regulator adjustment screw clock-wise to

increase the pressure and counterclockwise to decrease it.

3. Replace the pressure regulator adjustment screw cap.

Never force the regulator adjustment screw beyond the stop

limits or damage to the regulator will occur!

Required Gas Pressure

Provide gas supply pressure at inlet to boiler gas train as follows:

LP

Nat

Minimum (in. W.C.)

2

2

Maximum (in. W.C.)

14

14

Measure pressure when the boiler is fi ring at full rate. Low

gas pressure could indicate undersized gas line or insuffi cient gas

supply.

“Static and operating gas pressure required at the gas valve inlet is

between 2" W.C. and 14" W.C. for natural gas and 2" W.C. and

14" W.C. propane. If the gas pressure is above this limit, a lock-up

style regulator suitable for dead end service such as an Equimeter

or Fisher must be installed to prevent increase (creep) of gas

pressure when the units are not operating. Th is pressure regulator

(supplied by others) may be installed at the service entrance to

each unit or a “master” regulator sized to handle multiple units may

be utilized. Consult local gas utility or regulator manufacturer for

recommendations to meet specifi c job site requirements.”

Input Rate, Natural Gas

Gas appliances are rated based on sea level operation with no adjust-

ment required at elevations up to

2000 ft

,

610 m

. At elevations

above

2000 ft

,

610 m

input ratings should be reduced by 4% for

each

1000 ft

,

305 m

.

Check the input rate as follows:

1. Turn off all other gas appliances that use the same gas meter

as the boiler/water heater.

2. Call your gas supplier and ask for the heating value of the gas.

3. Start the boiler/water heater and let it run for 15 minutes.

4. Using the gas meter and a stopwatch, clock the time that it takes

to burn

10 ft

3

,

0.28 m

3

of gas and divide this time by 10.

5. Insert the heating value and the time, in seconds, into the formula

below.

6. Input = (heating value, Btu/hr)(3600)/(time, seconds)

7. If the computed rate deviates by more than 5% from the rated

input value of the unit, consult factory.

Never increase the input to the boiler/water heater

above that for which it is rated. Doing so can cause

premature failure of the boiler!