Tiller brackets

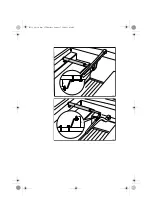

If the tiller is higher or lower than the mounting socket, you can use a

Raymarine tiller bracket to vary the tiller pin offset so the drive is

horizontal.

Identifying the correct tiller bracket

1. Clamp the tiller on the boat’s center line.

2. Measure dimension D (if the pushrod is above the tiller) or

dimension E (if the pushrod is below the tiller).

3. Select the appropriate bracket from the following table:

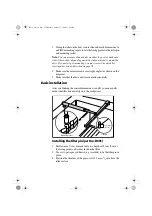

Mounting the tiller bracket

1. Position the tiller bracket on the center line of the tiller (above or

below) and establish the critical dimensions

A

and

B

Note:

To measure dimension

B

on a boat with a sloping rudderstock,

refer to the diagram on page 56.

2. Mark the centers of the two bracket mounting holes.

3. Drill two 6 mm (

1

/

4

in) diameter holes through the center line of

the tiller at the positions you have marked.

4. Attach the tiller bracket using two 6 mm (

1

/

4

in) diameter bolts,

nuts and washers.

5. Bond the fixing bolts in place with two part epoxy adhesive

6. When the epoxy is completely hardened, fully tighten the nuts.

7. Attach the tiller pin to the bracket.

Dimension D

(pushrod below tiller)

Dimension E

(pushrod above tiller)

Bracket

part no.

25 mm (1 in)

51 mm (2 in)

D009

51 mm (2 in

76 mm (3 in)

D010

76 mm (3 in)

102 mm (4 in)

D011

102 mm (4 in)

127 mm (5 in)

D159

127 mm (5 in)

152 mm (6 in)

D160

81131_8.book Page 54 Thursday, October 7, 2004 11:03 AM

Содержание Q047

Страница 2: ...81131_8 book Page 118 Thursday October 7 2004 11 03 AM...

Страница 11: ...D286 2 D E D287 2 81131_8 book Page 55 Thursday October 7 2004 11 03 AM...

Страница 19: ...81131_8 book Page 118 Thursday October 7 2004 11 03 AM...

Страница 21: ...User notes 81176_4 fm Page 22 Tuesday April 18 2006 9 26 AM...

Страница 22: ...User notes 81176_4 fm Page 22 Tuesday April 18 2006 9 26 AM...

Страница 23: ...User notes 81176_4 fm Page 22 Tuesday April 18 2006 9 26 AM...

Страница 24: ...www raymarine com...