nVent.com | 3

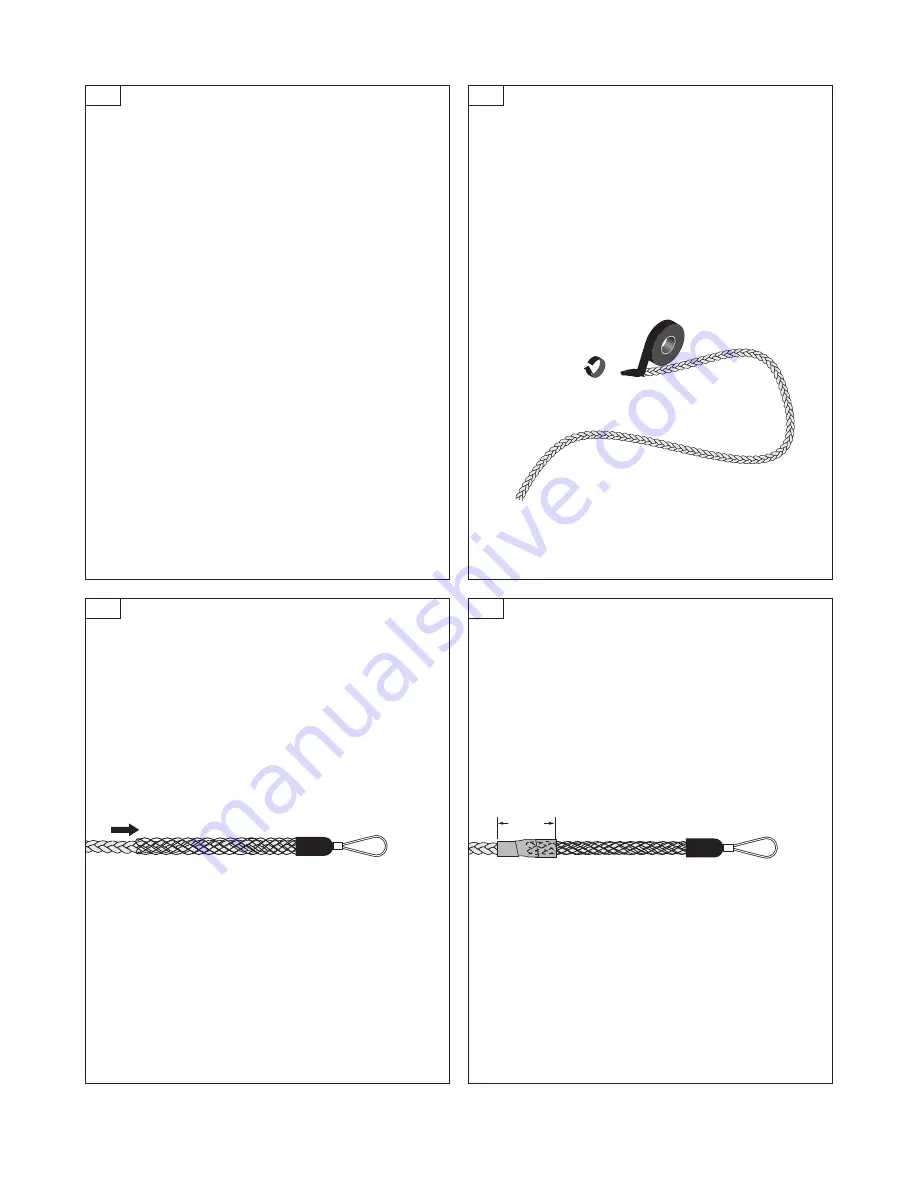

2 in

(50 mm)

Tape over here.

3A

3C

3B

3D

Install sensing cable in accordance with the leak detection

layout plan.

Planning the cable pull:

• Verify that each end is terminated in a rope overbraid

loop. Identify which end of the cable (Pin or Socket) is

on the outside of the reel by examining the label near the

overbraid loop.

• Attach the pull rope to the rope overbraid loop only

after planning the direction of the cable pull based

on which cable end is on the outside of the reel.

Note the PIN connector end of cable is always

oriented towards the TraceTek alarm module.

• If PIN connector end is on the outside of reel, pull cable

into conduit towards the TraceTek alarm module.

• If SOCKET connector end is on the outside of reel, pull cable

into conduit away from the TraceTek alarm module.

Common mistakes include pulling the cable into the wrong

conduit, and pulling the wrong end of cable into the conduit.

Before pulling the cable into any conduit, verify that correct

conduit is being used. Good conduit installations will use a

strategy to mark conduits. Check with project supervisors

if any doubt exists as to how the conduit is labeled. Errors

in conduit identification and cable orientation can result in

compromised cable quality.

• Insert the end of the rope braid as far as possible into

the cage end of the Kellems grip.

Attach the Kellems grip (if necessary):

• For TT500X-HS bulk cable, you may need to use a

Kellems grip to perform the cable pull when the rope

overbraid loop is not available.

• Make sure the end of the sensing cable has been

properly prepared.

• The end of TT500X-HS sensing cable should be sealed

with heat shrink tubing, and the end of the rope braid

should be taped to form a tapered end.

• Tightly wrap electrical tape over last 1 inch of the

Kellems grip cage, and also over 1 inch of the rope

braid. Make a smooth transition with the tape. The tape

is necessary to prevent the Kellems grip cage from

releasing the cable in the event of a backwards pull.