2 | nVent.com

1

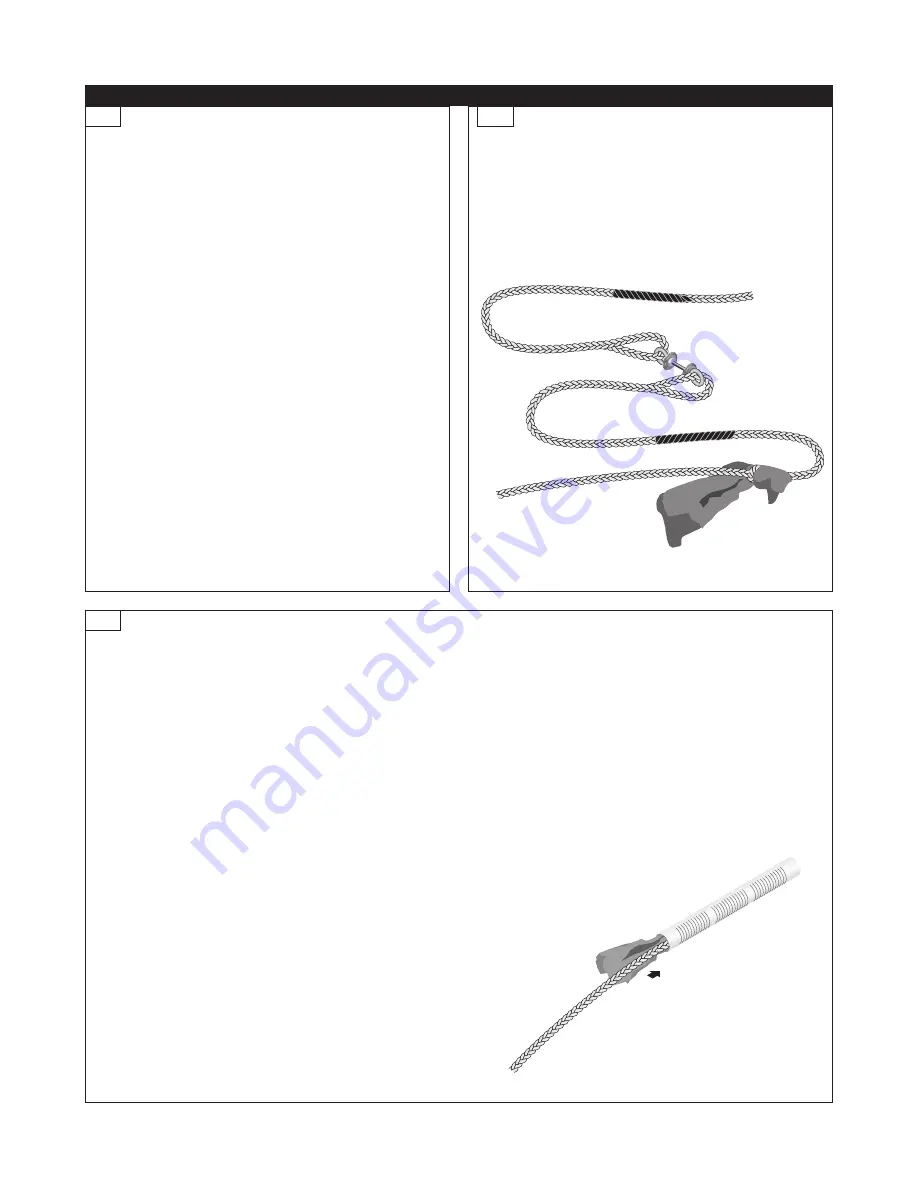

2B

2A

Prepare the conduit and pull rope.

• Verify that major construction is complete.

• Verify conduit and pull rope has been installed

properly. Reference TraceTek document

H58175 for general information.

Note that conduit dimensions and related parts can vary

between projects.

• Verify that the pull rope is free of knots and splices

and that there is 6 feet of extra rope at both ends of

each section.

• Two people are needed to manage the pull rope. One

person is on each end of the end pull rope, and each

person must be able to communicate with the other in

case of problems during the pull.

• The person feeding the pull rope into conduit needs to

maintain slack at all times.

• Pull the sizing tool from one end of the conduit

section to the other.

• Verify that the sizing tool pulls freely through

each section of conduit. Pull with a slow steady

motion. Do not use excessive force on the pull

rope, as this could damage the conduit.

• As you pull, coil the pull rope by hand and keep the

pull rope out of the dirt by placing it on cardboard or

plastic sheeting.

• If the pull rope becomes stuck, do not increase

pull force-instead pull the rope in opposite

direction for a short distance, then try repulling

in original direction with normal force.

• Shake the rag attached to the sizing tool free of excess

debris. Remove the rope section containing the rag

from the sizing tool. Replace the rag with a clean rag if

necessary, and then attach the rope section with the rag to

the eye splice in advance of the sizing tool.

• Reverse the pulling direction to bring the sizing tool

through the conduit in the opposite direction, and return the

original pull rope back into the conduit. Remove the sizing

tool and rope section with rag from the pull rope.

• Verify conduit ends are marked for example, with different

color conduit endcaps or tape to indicate direction

(towards or away) relative to TraceTek alarm module.

• Arrange excess pull rope by coiling around the riser pipe

and taping in place.

• Cover conduit ends to maintain cleanliness within conduit.

Use a plastic bag taped in place, or stuff a clean rag into

conduit end.

Conduit Cleaning:

• Even if the conduit was proofed with a conduit cleaning

tool during the conduit installation process, it is

recommended to clean and check clearance of the

conduit immediately before installing cable in order to

avoid damaging the cable.

• Attach a rope section with a rag tied to the eye splice in

advance of the sizing tool.

Installation