The chimney must be swept before installation.

Erecting New Chimney

The flue through the chimney should be formed with pre-cast

moisture and acid-resistant liners with a minimum internal

dimension of 185mm square and all in accordance with the

current Building Regulations (England and Wales) and in

Scotland the Building Standards (Scotland) (Consolidation)

Regulations and the Codes of Practice for chimneys and flues

BS. 6461 Part 1 and BS 7566 Parts 1 to 4.

Ensure the chimney liners are free of projecting internal

building jointing composition before the appliance is installed.

Factory made Insulated Chimneys

It is recommended the chimney be ceramic lined and comply

with BS. 4543.

The minimum diameter for a straight chimney is 175mm and if

offsets are fitted the recommended minimum diameter is

200mm.

There are two Isokern pumice liners which are also

recommended. One is the standard 175mm diameter and the

other is a 170mm thin wall. The thin wall has a smaller outer

diameter and is designed to fit an existing chimney system.

Both have a lifetime guarantee.

IN ALL TYPES OF CHIMNEYS THE MINIMUM HEIGHT FOR

CORRECT OPERATION OF THE COOKER IS 4.8m AND

SHOULD TERMINATE ABOVE THE ROOF IN ACCORDANCE

WITH REGIONAL STATUTORY REQUIREMENTS.

RECOMMENDED FLUE DRAUGHT - 20Pa/.08 WG MINIMUM.

THE APPLIANCE SHOULD BE INSTALLED AND CONFORM

TO THE CURRENT CODES OF PRACTICE FOR

INSTALLATION OF DOMESTIC HEATING AND COOKING

APPLIANCES BURNING SOLID FUEL - BS 8303.

ALWAYS ADVISE THE USER TO CLEAN THE COOKER

FLUES IN ACCORDANCE WITH THE OPERATING

INSTRUCTIONS AND TO HAVE THE CHIMNEY SWEPT AT

A MINIMUM OF 6 MONTHLY INTERVALS AFTER THE

COOKER IS COMMISSIONED. A VISUAL INSPECTION

SHOULD BE CARRIED OUT MONTHLY.

WARNING: PROLONGED SOOT FORMATION MAY RESULT

IN THE FLUEWAYS BECOMING BLOCKED AND COULD

GIVE RISE TO THE RELEASE OF CARBON MONOXIDE, A

POISONOUS GAS, INTO THE ROOM.

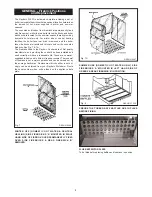

The position of available types of flue layouts are shown in

Figs. 2, 3 and 4, the cooker flue chamber is adaptable to

provide either top or back flue outlets, by means of the

reversible loose socket.

(a)

Rear Flue Outlet

This must only be used where there is a brick flue

immediately behind the cooker. Provision must be made for

a condensate collecting vessel and cleaning door. See Fig. 3.

NOTE:

EXTENDED REAR FLUE PIPE AND BENDS ARE NOT

RECOMMENDED.

(b)

Top Flue Outlet

The cooker should be connected to the main flue via a

150mm minimum diameter cast iron pipe or appropriately

sized vitreous enamelled mild steel pipe and be sealed to

the cooker flue chamber with soft rope and fire cement.

Any bends in the flue pipe must be not less than 135º (45º

from horizontal) and be complete with a cleaning door.

A minimum 6” vertical length of flue pipe must be fitted before

any bend is included.

Fig. 2

Fig. 3

Fig. 4

3

DESN 515206

DESN 515207

DESN 515208 A

COOKER FLUE CONNECTION