Place the cooker in the intended position and lift out the surface

ground hotplate, checking that the joint between the underside

of the hob and the top of the cooker is intact.

Any joints which have opened should be made good with fire

cement provided.

If the appliance is installed near combustible material then as

well as adhering to minimum clearances in Fig. 1 additional

non-combustible insulation must be fitted to the wall to protect

the area around the flue and fluebox. The insulation must reach

a minimum distance of 150mm either side of the flue/flue box

and follow the line of the flue. The minimum specification for

this material is Superwool 607 LTI with a density of 320kg/m3,

a thickness of 10mm and a self finish. There must be a

minimum 16mm air gap between the insulation board and an

adjacent combustible wall surface. A higher specification

material may be used but the air gap must be maintained

.

Check that the boiler/cooker flueway dampers operate correctly

by turning the knob on the front plate adjacent to the top left

hand corner of the roasting oven door.

NOTE: IT IS NOT VISUALLY POSSIBLE TO SEE THE

BOILER DAMPER AND THIS SHOULD BE CHECKED BY

FEELING THROUGH THE HOTPLATE APERTURE TO THE

BACK OF THE COOKER. THE COOKER DAMPER SPINDLE

OPERATES THE BOILER DAMPER WHICH CAN BE FELT

BY INSERTING HAND INTO FLUEWAY.

Replace the hotplate making sure that it is seating evenly on

the soft rope and that it is approximately 1.5mm proud of the

enamelled top plate, with an equal space all round.

1. Connect pipework to boiler flow and return tappings.

2. Fit the flue chamber which should have a rope seal already

installed. The flue chamber is screwed to the cooker making

a good seal as any air leak at this point will impede the

working of the cooker.

3. Open the firebox and ashpit doors and check that the

reciprocating bottomgrate bars are in position, and the 3

grate plates are in place. The riddling lever will not operate

fully as these plates, if fitted correctly, will lock the

reciprocating bars.

4. Turn the boiler thermostat knob at the rear left hand corner

of the top plate from No.1 (low) to No.8 (high).

NOTE: THE HIGHER THE NUMBER, THE HIGHER THE

WATER TEMPERATURE.

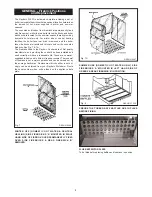

The handrail brackets are held on the front ends of the cooker

top-plate casting. Remove the travel nuts and replace with the

handrail brackets ensuring the fibre protecting washers are in

position. Insert the handrails with fitted endcaps into the

brackets, positioning them correctly, and tighten the locating

bolts (Fig. 9).

After completing the installation, the heating contractor should

demonstrate to the user the operation of the appliance and the

routine cleaning method.

The protective grease should be removed from the hotplate

before lighting.

Check that the system is full of water and free from air locks.

When lighting, check that the cooker flueway damper is set to

‘C’ cooker, the flue box damper is fully out and the chamber

door is closed, The thermostat should be at 8, maximum and

the spinwheel open. The secondary air slide inside the firebox

door should be set to open. These settings will allow maximum

draught for the firebox and flue. The cooker must not be left in

this condition, as the open spinwheel is not controlled

thermostatically.

The firebox door and the ashpit door are interlocked so the top

door has to be opened before the bottom. Add paper and

kindling to the grate and light. Close both doors. After a few

minutes the fire should pick up and gradually add larger pieces

of fuel. Allow the cooker to establish the fire and gradually

reduce the amount of air going into the firebox. Start closing

down the spinwheel, so that the cooker is working on the

thermostat. It may be that in normal running the spinwheel

needs to be slightly open depending upon the heat

requirement.

For the first couple of days do not overfire. The cast iron inside

the cooker will build up heat gradually and overfiring may cause

damage.

NOTE: SMOKE/SMELL EMITTED DURING INITIAL USAGE

Some parts of the cooker have been coated with a light

covering of protective oil. During initial operation of the cooker,

this may cause smoke/smell to be emitted and is normal and

not a fault with the appliance, it is therefore advisable to open

doors and or windows to allow for ventilation. Lift the lids to

prevent staining the linings.

7

TESTING AND COMMISSIONING

INSTALLATION

DESN 510454 A

Fig. 9