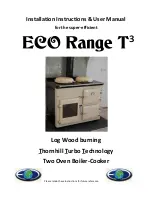

The cooking performance features of the popular and

proven solid fuel Rayburn Cookers have been

preserved and integrated into the Rayburn Cookmaster

200K and Rayburn Cookmaster Plus 208K

burning 28

Second Kerosene to BS: 2869: 1988 Class C2.

The Rayburn Cookmaster 208K provides domestic hot

water and cooking facilities, whereas the Rayburn 200K

provides cooking facilities only, which consists of a heat

graduated hotplate, main oven and warming oven. The

circulator oil burner is controlled by a manually operated

oil valve control knob. The burner should always be

continuously burning at low fire rate when not required

for cooking. When cooking is required, the burner

operates at a high fire rate by adjustment of the control

knob and its setting.

NOTE:

FOR LONG SHUT-DOWN PERIODS, CLOSE

ALL OIL VALVES BETWEEN THE OIL TANK AND THE

APPLIANCE.

WARNING:

OIL BURNER: NEVER ATTEMPT TO

RELIGHT A HOT BURNER - DO NOT TURN OIL ON

UNTIL BURNER IS COOL.

NOTE: SMOKE/SMELL EMITTED DURING INITIAL

USAGE.

Some parts of the cooker have been coated with a light

covering of protective oil. During initial operation of the

cooker, this may cause smoke/smell to be emitted and

is normal and not a fault with the appliance, it is

therefore advisable to open doors and or windows to

allow for ventilation. Lift the lids to prevent staining the

linings.

Users Instructions for Rayburn

Cookmaster 200K and Rayburn

Cookmaster 208K Oil Fired Cooker

07/06 EOPI 511030

1

INTRODUCTION

I M

P

O

R

T

A

N

T

The cooker burner is intended to run in a

continuously alight condition at all times,

at low fire rate when idling. Turning

the cooker burner OFF

is NOT

recommended unless servicing

is required or when the

cooker is left

unattended

for several

days.

Consumer Protection Act 1987

As responsible manufacturers we take to make sure that our

products are designed and constructed to meet the required safety

standards when properly installed and used.

IMPORTANT NOTICE

: PLEASE READ THE

ACCOMPANYING WARRANTY.

Any alteration that is not

approved by Aga, could invalidate the approval of the appliance,

operation of the warranty and could also affect your statutory

rights.

Control of Substances - Health and Safety

Important

This appliance may contain some of the materials that are

indicated.

It is the Users/Installers responsibility to ensure that the necessary

personal protective clothing is worn when handling, where

applicable, the pertinent parts that contain any of the listed

materials that could be interpreted as being injurious to health and

safety, see below for information.

Firebricks, Fuel beds, Artificial Fuels

- when handling use

disposable gloves.

Fire Cement

- when handling use disposable gloves.

Glues and Sealants

- exercise caution - if these are still in liquid

form use face mask and disposable gloves.

Glass Yarn, Mineral Wool, Insulation Pads, Ceramic Fibre,

Kerosene Oil

- may be harmful if inhaled, may be irritating to skin,

eyes, nose and throat. When handling avoid inhaling and contact

with skin or eyes. Use disposable gloves, face-masks and eye

protection. After handling wash hands and other exposed parts.

When disposing of the product, reduce dust with water spray,

ensure that parts are securely wrapped.

Better than you ever imagined