2

6823346-R3

P

ERIODIC MAINTENANCE

IMPORTANT:

Only trained and authorized personnel are

allowed to service iFork assemblies. Other maintenance

procedures are the sole responsibility of the purchaser.

IMPORTANT:

To prevent weighing inaccuracies, the end

user is responsible to check accuracy on a regular basis

at intervals that best fit their application and requirements.

Development of a periodic schedule will prevent faulty

readings. Cascade recommends a

minimum

interval of

every 12 months or 2000 hours, whichever comes first.

1.1

100-Hour Maintenance

Every time the lift truck is serviced or every 100 hours

of truck operation, whichever comes first, complete the

following maintenance procedures:

• Check for debris between fork and fork shoe (e.g. wood

chips).

• Inspect the bottom of the forks for debris that might be

wedged between the fork and the fork shoe. Remove

any debris found.

• Check for pinched wires at bottom of batteries.

• Tighten fork shoe capscrews after initial 100 hours of

service. Tighten to a torque of 80 ft.-lbs. (112 Nm).

As necessary, replace a cover spool, fork shoe

capscrews and nuts.

• Every 100 hours or when the battery packs are changed,

inspect the battery holders for damage and debris.

Remove any debris found and check to make sure that

the capscrews are tight and contact tabs not damaged

or bent. If required, tighten the contact point capscrews.

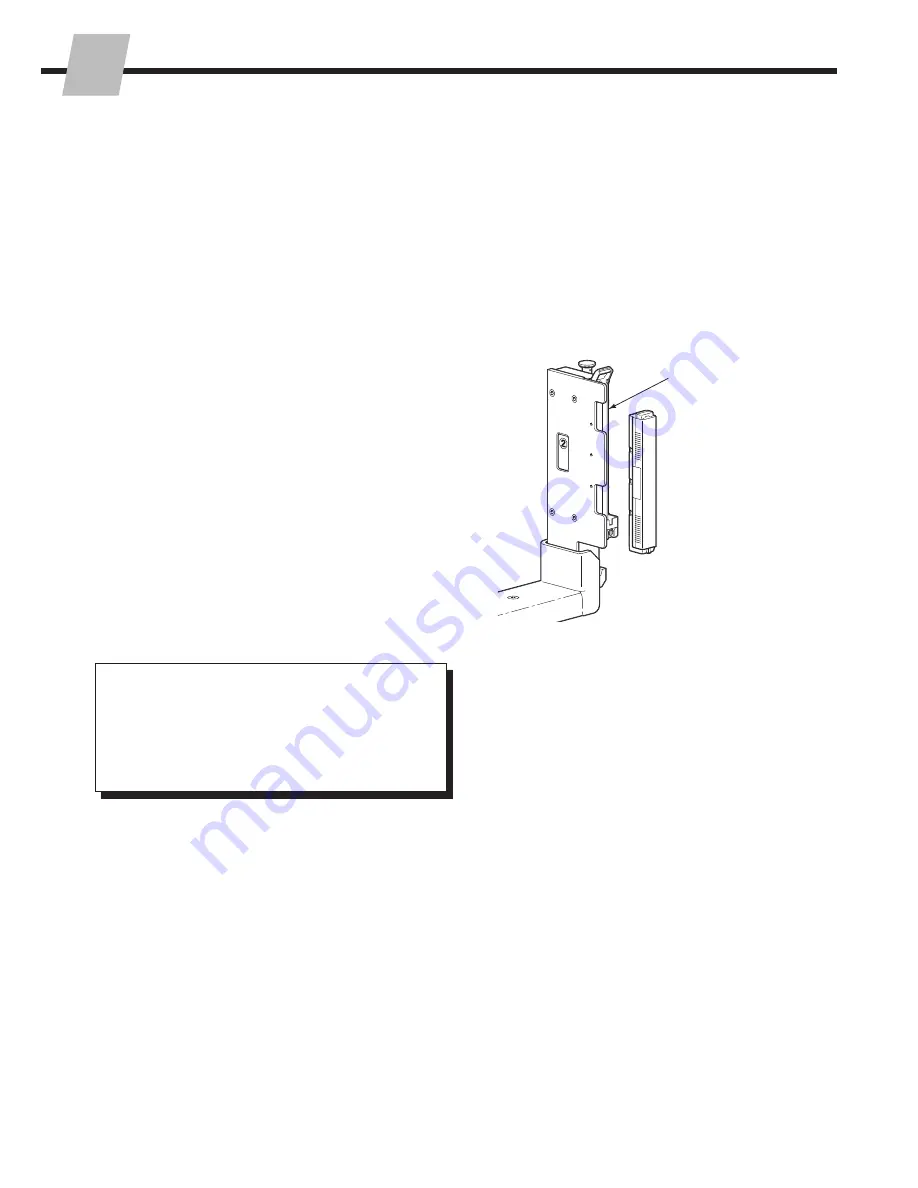

FK0176.eps

Battery Holders

Check capscrews, contact

tabs and contact point

capscrews

Cleaning iForks

As required, use a mild cleanser and wipe down

the forks with a towel. Rinse the fork with a

non-pressurized stream of water.

CAUTION:

Do not rinse display.