6

EN

4. PRODUCT DESCRIPTION

The fixture described in this manual is a pneumatic cutting unit model FP120M which can be

assembled on automatic machines (e.g. spreaders, computerized cutting). FP120M can operate

continuously and it can cut at various heights by means of multiple installation. Thanks to

the presence of a 1HP pneumatic motor, FP120M is able to cut difficult materials with

thickness up to 50 mm. It is particularly suitable for technical fabrics and composite materials.

By cutting with the blade and the counterblade always in contact and thanks to the steel

upper quality of the blade supplied, FP120M guarantees the clean separation without frayings

of the two borders of the cut material. One special feature of cutting unit FP120M is its ability

to sharpen the blade in each moment without disassembling it by means of a emery grinding

wheel mounted on the cutting unit head. After carrying out this operation, it is possible to

start cutting again. The pneumatic cutting unit is provided with a threaded connection suitable

for most of the air pipelines. A high power motor, perfectly balanced, with a high number of

revolutions and totally free of maintenance, reduces the vibrations to the minimum, thus

making the cutting unit comply with European Directive No. 2002/44/EC concerning the

risks deriving from mechanical vibrations. The cutting unit can be used also to cut damp or

wet materials; therefore it is recommended in tanneries, dyeworks, etc. The use of compressed

air as source of energy allows working continuously without problems of heating or motor

overload. The mechanical parts are made up of high quality steel, bronze and aluminium and

require a lubrication after many working hours.

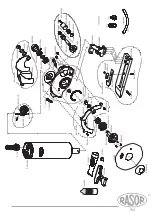

4

1

2

7

9

5

6

8

12

11

10

3

13

1

Silencer

8

Hard metal counterblade

2

1/4" gas connection for the air

connector

9

Aluminium base covered with

Teflon

®

3

Closing plug

10

Motor support

4

Pneumatic motor

11

Sharpening button

5

Rear protection guard

12

Greaser

6

Poligonal blade

13

Steel structure

7

Front protection guard

Device components

Содержание FP120M

Страница 1: ...PNEUMATIC CUTTING UNIT USE MANUAL FP120M...