11

11

P104E** Units Require

• Wire

• Wire cutters

• Wire terminal crimpers

• Terminals

• Fuse/circuit breaker

SPECIFICA

TIONS

FOR WIRING

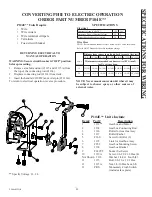

CONVERTING PHII TO ELECTRIC OPERATION

ORDER PART NUMBER P104E**

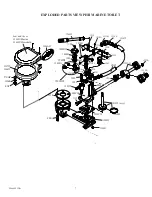

Item# Part# Description

1

1131**

Gearbox and Motor

2

1134

Gearbox Connecting Rod

3

1136

Roller for Gearbox Assy

4

1137

Roller Washer

5

F360

Screw for Roller (3)

6

1135

Link for Gearbox Assy

7

F359

Gearbox Mounting Screw

8

1138

Gearbox Bracket

9

F149VT

Socket Set Screw

10

1119A

Screw, 1/4-20 x 1/2 Hex (4)

Not Shown 1118

Washer, 1/4 Ext. Tooth (4)

11

1115

Bolt, 3/8-16 x 1 1/2 Hex

12

1115A

Nut, 3/8-16 Hex Jam, S/S

13

PRS

Momentary Flush Switch

(includes face plate)

** Specify Voltage: 12, 24

P104E** Units Include

RETURNING ELECTRICAL TO

MANUAL OPERATION

WARNING: Secure circuit breaker in "OFF" position

before proceeding.

1. Remove arm bolt and nut (#1115 and #1115A) from

the top of the connecting rod (#1134).

2. Displace connecting rod (#1134) from track.

3. Insert the handle (#1208W) and cotter pin (#1210A).

To return to electrical operation, reverse procedure.

12

11

UNIT’S

VOLTAGE

12 12 (6.0) 10 (6.0) 10 (10.0) 8 (16.0) 8 (16.0) 6 (16.0) 6 (25.0)

24 16 (1.5) 16 (2.5) 14 (4.0) 12 (4.0) 12 (6.0) 10 (6.0) 10 (10.0)

Nominal Voltage (Volts DC)

12V

24V

Amperage Draw @ Nominal Voltage

15

8

Circuit Breaker/Fuse Size (Amps)

20

15

Electrical

SPECIFICATIONS

Minimum recommended conductor wire AWG (mm

2

)

for 3% voltage drop

10' (3.1) 15' (4.6) 20' (6.1) 25' (7.2) 30' (9.2) 40' (12.2) 50' (15.2)

Distance from source to unit and back to source [feet (m)]

Wire Sizes

NOTE: Recommended conductor sizes based on 105C rated insulation.

Refer to ABYC Standards for other insulation ratings.

NOTE: Never mount conversion kit where it may

be subject to shower spray or other sources of

external water.

L584v0222jlc