3

MAINTENANCE

Super Lube

®

(#SL1CC) applied to the piston rod will

prolong the life of the Piston Shaft Seal. This should be

done every spring and fall or more regularly if the head

is used frequently. Applying Super Lube to all moving

parts is also recommended.

Installation of a Knocks Out Odor Kit (#KO2) will

reduce the "rotten egg" smell associated with using salt

or brackish water to flush the toilet.

Before attempting repairs, refer to the

Troubleshooting section of this manual.

WINTERIZING

Improper winter lay up is a major cause of marine

toilet failures.

Parts Required

• 3/4" I.D. intake hose approximately 3 feet long.

• 1 1/2" I.D. discharge hose approximately 3 feet long.

• Two buckets

• Nontoxic antifreeze approximately 1 quart

1. Close the intake and discharge seacock. Disconnect

and drain the intake and discharge hoses.

2. Connect short hoses to toilet’s intake and discharge.

3. Place one bucket under short hose on discharge.

4. Pour nontoxic antifreeze in other bucket.

5. Place hose connected to intake into bucket with

antifreeze.

6. Flush toilet until antifreeze begins to be discharged

from toilet.

7. Antifreeze should remain in the toilet until

recommissioning. This will protect both intake and

discharge sides of the pump. Pouring antifreeze into

the bowl will only protect the discharge.

NOTE: Holding tanks, seacocks and treatment

systems need to be independently winterized,

stored and recommissioned (see manufacturer’s

instructions).

RECOMMISSIONING

1. Lubricate piston rod with Super Lube

®

.

2. Using the buckets, hoses and a gallon (3.8 liters)

of clean water, flush the antifreeze out of the toilet.

Dispose of antifreeze properly, in accordance with

local and federal regulations.

3. Reconnect the hoses and open both seacocks.

4. Check all connections for leaks with several test

flushes.

MAINTENANCE\WINTERIZA

TION

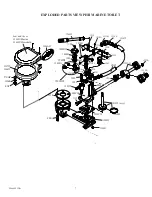

NOTE: Before reinstalling

1209BW valve handle, be

sure points "A" and "B"

on the inlet valve body

(#1203BW) are positioned

as shown by the double

arrow.

POINT "B"

Toilet

Base

Toilet

Base

Correct Orientation of

#1228CW Flapper Valves

FIG 2

CORRECT!

POINT "A"

WRONG!

INSTALLATION OF REPLACEMENT

PARTS

1. Refer to Fig. #2 when replacing part #1228CW.

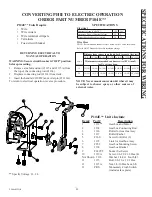

2. If valve body (#1203BW) is removed it

must be positioned as in Fig. #3 for proper

operation.

Overhaul kits and individual parts for your toilet

may be ordered through your dealer or direct

from the factory.

FIG 3

3

L584v0222jlc