13

• No Power to unit

Check circuit breaker or main fuse to unit

Check wiring to unit

• Open or loose connection

Check and clean wiring connections

• Display

Check display for errors

• Inoperative control indicator panel

Check, replace if necessary

• Damage to control indicator panel cable

Check, replace if necessary

• Extreme low voltage when unit starts

OVERLOAD ERROR/ FUSE ERROR

• Motor overload

check motors for jam and reset

overheating, cool down and reset

check fuse on mother board

• Electrode overload

Excessive salt, shorted wiring, bad electrode.

•POS fuse blown

check toilet relay or salt feed pump and wiring. replace fuse

• NEG fuse blown

Check toilet relay or salt feed pump and wiring, replace fuse

LOW AMP ERROR OR WARNING ON DISPLAY

• Low salt

Add salt to system, install salt feed system if

operating in fresh or brackish water

• Dirty electrode pack

Clean following instructions in Maintenance

• Nonfunctioning electrode pack

Check, replace if necessary

LOW VOLTAGE ERROR OR WARNING

• Low voltage

Discharged or bad battery, charge or replace

• Drop in line voltage

Check voltage between pos post and negative post

• Other equipment on same circuit as Electro Scan

Isolate Electro Scan

• Open or loose connections

Check and clean wire connections

Sewage Odor

• Odor permeating through hose or connections

Rub damp rag on hose, if odor transfers to rag hose

needs to be replaced with high quality sanitation

hose Raritan part # SH

• Treatment unit is leaking

Follow discharge hose from toilet to tank, check area

around motors too

• Electrode not functioning properly

Check readings on LCD Display for error or warning

• Electro Scan not being activated with each flush

System must be activated with each flush

• Treatment unit not being stored properly

See Storage under Maintenance

TROUBLESHOOTING

When "Push to Flush" doesn't activate system

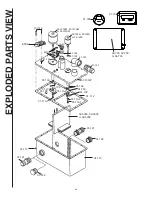

How to remove microprocessor board

microprocessor board

•

Turn off power

•

Open control unit cover

•

Microprocessor board can be pulled out

without disconnecting any wires

•

Install replacement board

•

Use anti-static bag to pack board for return

to dealer/factory

•

NOTE:

Static electricity will damage the

board, use precaution and proper grounding

to avoid static build-up while working with

the microprocessor board.

Содержание Electro Scan EST12

Страница 12: ...12 This page left blank...