CONTROL BODY MOUNTING

Select a location that will permit proper capillary routing. It is

important not to twist or strain the control body as shifting of the

calibration may result.

RANCO pressure controls can be mounted in any position,

either vertically or horizontally, without affecting performance. The

control can be mounted on an existing bracket, on the bracket

provided, or can be flush-mounted without a bracket. Whichever

method is selected, use only the mounting holes provided; no

other holes are to be added to the control frame.

1. Secure the control to a bracket with the 10-32 x 3/16

screws

by using the two tapped holes in the back of the control.

If other mounting screws are used, they must not

protrude into the control more than 1/8” to avoid

damage.

2. When using the angle bracket, the control can be mounted to

the compressor or any flat surface by using two or more of

the four slotted holes in the base of the angle bracket.

3. When flush mounting the control, use the .20 inch holes in

the back of the control frame. Access can be gained by

removing the front cover an securing

the control body to a wall or any flat surface.

Mounting to an uneven surface may cause improper

control operation.

CAPILLARY CARE AND MOUNTING

Compressors vibrate. Copper work-hardens and fractures when

flexed beyond its physical limits. Combine these two factors

and broken capillaries can result. Breakage can be prevented by

proper installation practices.

1. Minimizes the number of times the capillary is bent. Each

time it is rebent, it work-hardens making it more susceptible

to breakage.

2. Avoid sharp bends, kinks, strains or pinch marks in the

capillary. Never allow the capillary to rest against sharp

edges or rub against metal surfaces where it can be

damaged by friction.

3. The capillary should be straight within 4 inches of the

pressure connection so the pulsations do not work-harden

the capillary.

4. Purge all tubing and lines before connecting pressure

controls.

5. Route the capillary so that it will be safe-draining to minimize

PREFERRED

H.P.

L.P.

No

Alternate

oil logging.

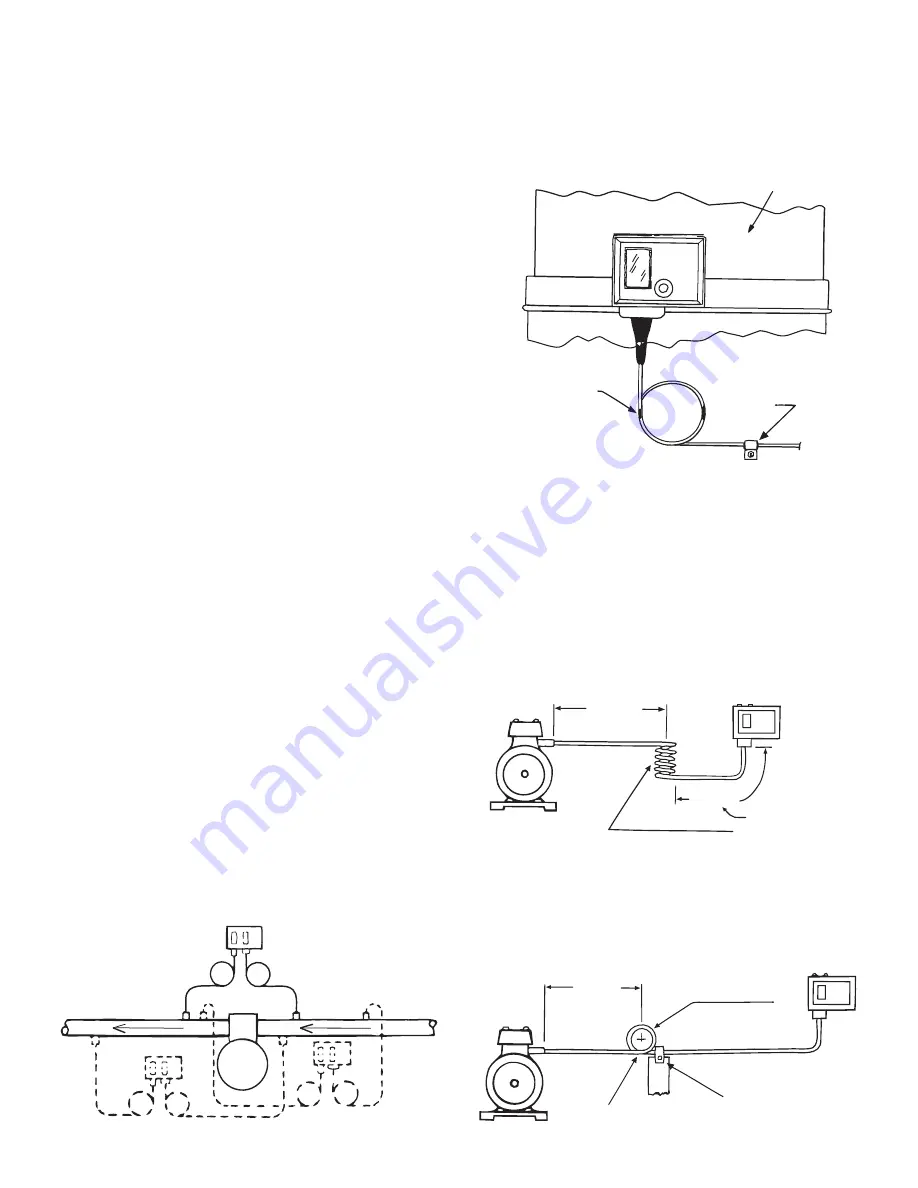

6. When the control is mounted directly on the compressor, the

capillary must be secured to the compressor so that ever

thing moves together. If the capillary or control is shaking or

vibrating against the compressor vibration, work-hardening

Plastic or

Rubber Lined

Clamp

Coils can be taped

or tied. See

notes 8, 9 & 10

Compressor

COMPRESSOR MOUNTING

of the capillary may occur, leading to eventual failure.

7. When the control body is mounted remote from the

compressor and the pressure connections are on the

compressor, vibration coils must be used between the

compressor and the mounted control. The coils should not

touch. A section of rubber pipe insulation inserted into the

vibration coils and secured with silicone adhesive will keep

the coils separated, yet allow them to absorb vibration.

The capillary between the vibration coils and the control body

should be secured to a stationary member when that distance

3” to 6”

If this distance is more

than 6”, the tubing

should be clamped

as shown below.

Min. of 2 Coils

2 to 3 Inch

Diameter Coils

12” to 18”

Control

Coils Should Not

Touch

Compressor

REMOTE MOUNTING

exceeds 6 inches.

The capillary between the vibration coils and the control body

should be secured to a stationary member when that distance

exceeds 6 inches.

12” Approx

Min. of 2 Coils

2 to 3 Inch Dia.

Coils

Clamp Tube to

Stationary Member

2 or More Coils of Tubing On

Compressor Side Clamp

Coils Should Not

Touch

Compressor

Control

REMOTE MOUNTING

2