7

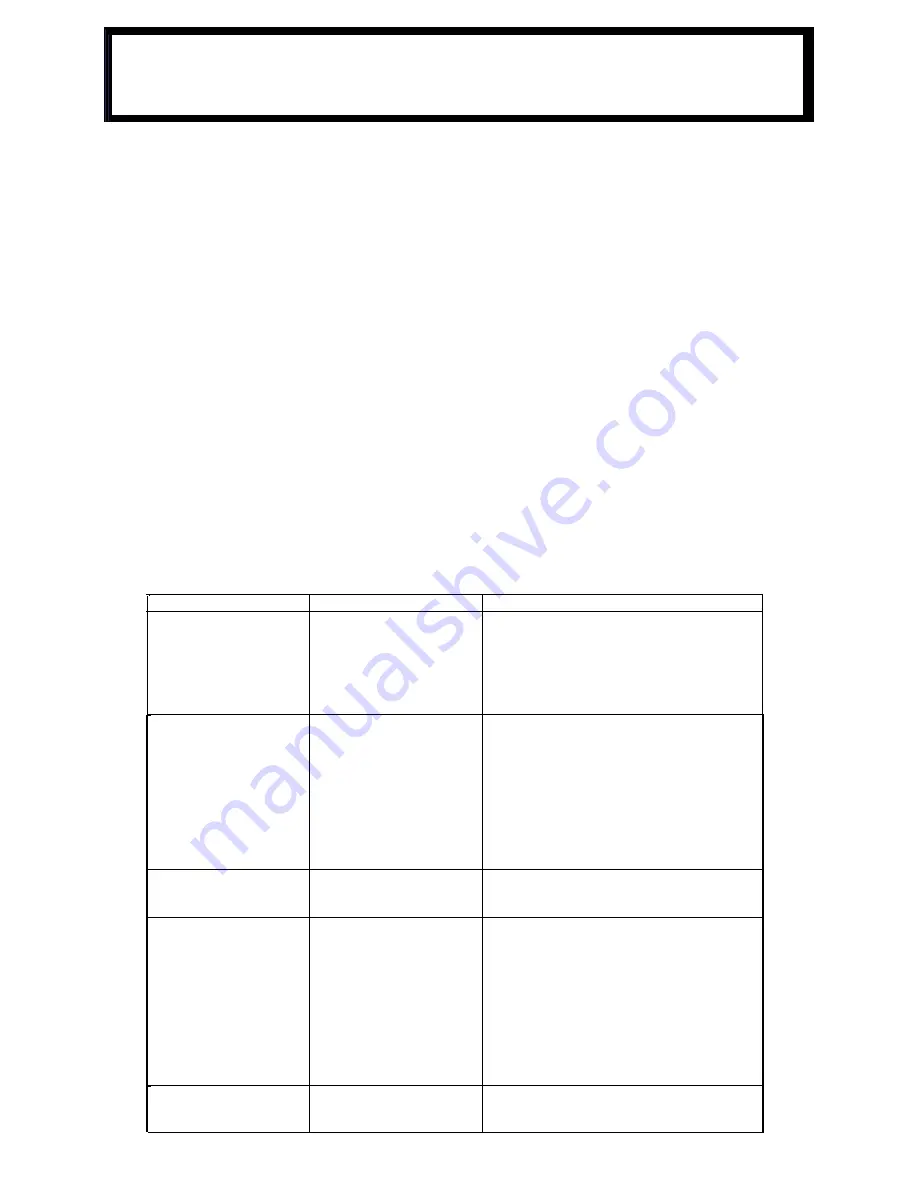

CONDITION

POSSIBLE CAUSE

CORRECTION

MOTOR RUNS IN ONE

DIRECTION ONLY

(1) Defective solenoid or stuck

solenoid

(2)Defective remote control

switch

(1) Jar solenoid to free contacts. Check by applying

12 volts to coil terminal (it should make an audible

click when energized).

(2) Disengage winch clutch, remove remote control

switch plug from the socket and jump pins at 8 and

4 o'clock. Motor should run.Jump pins at 8 and 10

o'clock. Motor should run.

MOTOR RUNS

EXTREMELY HOT

MOTOR RUNS, BUT WITH

INSUFFICIENT POWER,OR

WITH LOW LINE SPEED

(1) Long period of operation

(2) Insufficient battery

(3) Bad connection

(4) Insufficient charging system

(1) Cooling-off periods are essential to prevent

overheating.

(2) Check battery terminal voltage under load. If 10

volts or less, replace or parallel another battery to

it.

(3) Check battery cables for corrosion; clean and

grease.

(4) Replace with larger capacity charging system.

MOTOR RUNS, BUT DRUM

DOES NOT TURN

(1) Clutch not engaged

(1) If clutch engaged but symptom still exists, it will

be necessary to disassemble winch to determine

cause and repair.

MOTOR WILL NOT

OPERATE

(1) Defective solenoid or stuck

solenoid

(2) Defective remote control

switch

(3)Defective motor

(4) Loose connections

(1) Jar solenoid to free contacts. Check by applying

12 volts to coil terminal (it should make an audible

click when energized).

(2) Disengage winch clutch, remove remote control

switch plug from the socket and jump pins at 8 and

4 o'clock. Motor should run. Jump pins at 8 and 10

o'clock. Motor should run.

(3) If solenoids operate, check for voltage at motor

posts; replace motor.

(4) Tighten connections on motor.

MOTOR WATER

DAMAGED

(1) Submerged in water or

water from high pressure car

wash

(1) Allow to drain and dry thoroughly, then run

motor without load in short bursts to dry windings.

L

ubrication/Cable lnstallation

All moving parts in the winch are permanently

lubri cated with high temperature lithium grease at

the time of assembly. Under normal conditions,

factory lubrication will suffi ce. Lubricate cable

periodically using light penetrating oil. Inspect

for broken trands and replace if necessary with

Ramsey part number listed in Parts List. If the

cable becomes worn or damaged, it must be

replaced.

Unwind the new cable by rolling it out along the

ground, to prevent kinking. Remove old cable and

observe the manner in which it is attached to the

cable drum fl ange.

Before installing the new cable assembly, make

sure end of cable is squarely cut and wrapped

with tape to prevent fraying.

Troubleshooting Guide

Position the cable drum so that the large

13/32” diameter hole in the motor end drum

fl ange is approximately on the top. Form a

short bend (approximately 1/2” long) in the end

of the cable. Insert the bend into the 13/32”

hole in the drum fl ange and then carefully run

the winch in the “reel-in” direction approxi-

mately 3/4 revolution until the 1/4” diameter

threaded hole in the drum fl ange is on top.

Secure the cable to the drum fl ange using

cable anchor and capscrew. Securely tighten

the capscrew but do not overtighten.

Wind 5 wraps of cable onto the drum. Wind on

the rest of the cable by pulling in a light load to

keep the tension constant. Allow the cable to

swivel by using a length of chain or a swivel

block between the cable hook and the load.

LUBRICATION & CABLE INSTALLATION

Содержание Quick-Mount QM5000H

Страница 2: ......

Страница 3: ...3 SAFETY PRECAUTIONS OPERATION TIPS...

Страница 4: ...4 TECHNIQUES OF OPERATION...

Страница 11: ......

Страница 12: ...Ramsey Winch Company Post Office Box 581510 Tulsa Oklahoma 74158 1510 Telephone 918 438 2760 FAX 918 438 6688...