16

www.raider.bg

the hands of untrained users.

e) Maintain power tools. Check moving parts for normal operation and free movement, integrity and

serviceability of parts, and any other circumstances that may adversely affect the operation of the power tool.

If it is damaged, the power tool must be repaired before further use. Many accidents are caused by poorly

maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less

likely to block and are easier to operate.

g) Use the power tool, tool accessories and parts, etc. in accordance with these instructions and in the

manner prescribed for the specific type of power tool, taking into account the operating conditions and the

work to be performed. Using the power tool for work other than that for which it was designed can cause a

dangerous situation.

5) Service

a) Have your power tool serviced by a qualified service technician using only original spare parts. This

ensures that the power of the power tool is maintained.

2. Safety warnings when working with channel cutters

a) The fuse provided with the machine must be securely attached to it and positioned in such a way as to

ensure maximum safety so that as little of the disc as possible is exposed to the operator. The operator and

bystanders must stand away from the plane of rotation of the disk. The fuse protects the operator from flying

debris when the disc breaks and from accidental contact with it.

b) Use only reinforced abrasive or diamond discs. The fact that you can attach an accessory to your

power tool does not guarantee safe use.

c) The declared speed of rotation of the working tool must be at least equal to the maximum speed

indicated on the power tool. Work tools that rotate at a higher speed than declared may break and their

pieces may fly apart.

d) The discs should only be used for the prescribed applications. For example: do not grind with the side

surface of a cut disc. Diamond cutting discs are designed for peripheral cutting. Forces applied laterally to

the disc can cause it to break.

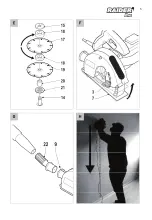

e) Always use undamaged disc flanges with the appropriate diameter for the selected disc. Properly

selected flanges secure the disc well, thus reducing the possibility of breakage.

g) The outside diameter and thickness of the work tool must be within the specified dimensions for your

power tool. Improperly sized work tools cannot be well protected or handled.

h) The connection dimensions of the discs and flanges must match exactly the size of the power tool

spindle. Discs and flanges with holes that do not fit into the power tool may cause unbalance, excessive

vibration, or loss of control.

i) Do not use damaged discs. Check the notched disc for each use and cracks. If the tool or disc is

dropped, inspect the disc for damage or install a new disc. After checking or installing the new disc, step

aside with all side watchers out of the plane of rotation of the disc and let the machine idle at maximum speed

for one minute. Damaged discs will usually break during this test.

j) Wear personal protective equipment. Depending on the application, wear a face shield, goggles or

face shield. If necessary, wear a dust mask, hearing protection, gloves or a protective apron to stop flying

particles.

and debris. Eye protection must protect against flying debris from various operations. The dust mask or

respirator must filter the particles released during operation. Prolonged exposure to loud noise may cause

hearing loss.

k) Keep bystanders at a safe distance from the work area. Everyone in the work area must wear personal

protective equipment. Flying debris from the workpiece or from a broken disc may cause injury beyond the

immediate area of work.

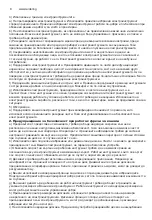

l) Only hold the power tool on insulated gripping surfaces when performing an operation in which the

cutting accessory may touch a hidden electrical installation or its own cord. The contact of the cutting

accessory with a live wire will place the exposed metal parts of the power tool live and the operator will

receive an electric shock.

m) Keep the power cord out of range of the rotating work tool. If you lose control of the power tool, the

power cord may be cut or hooked and drag your palm or hand within range of the rotating tool.

Содержание PRO RDP-WCH02

Страница 3: ...3 FIG A H ...

Страница 4: ...4 www raider bg ...

Страница 5: ...5 ...

Страница 76: ...76 www raider bg ...

Страница 79: ...79 ...