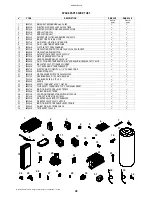

Installation Manual

Wall Hung Boiler with D.H.W. Storage Cylinder Low Nox – Cod. 99881NA – July 2001

17

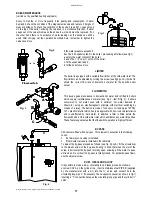

BOILER MAINTENANCE

(carried out by qualified heating engineers)

Every 12 months, or more frequently if the quality and consumption of water

demand it, check the condition of the magnesium anode and replace it if signs of

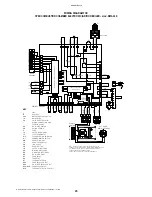

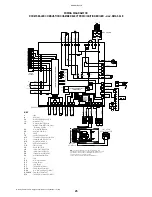

wear are evident. To check the condition of the anode 3 (see fig.1), open valve 4

on the top of the boiler, undoing the red knob in a clockwise direction. If water

seeps out of the valve this means the anode is worn and must be replaced. If on

the other hand there is no evidence of water leaking out, the anode can still be

used. After carrying out the operation described here, remember to tighten the

valve once more.

If the water pressure exceeds 6

bar, fit a 2 lt expansion tank to the boiler, proceeding as follows (see fig.1)

a. empty the water content of the boiler

b. undo the 1 / 2” cap (1) on top of the boiler;

c. fit the expansion tank 2;

d. fill the boiler once more.

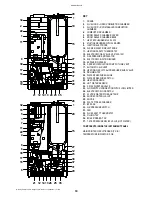

LIMITER

The boiler is equipped with a variable flow limiter at the cold water inlet. The

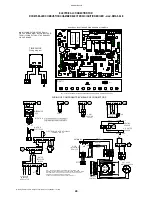

flow limiter can be adjusted by turning the screw (see fig.3 pos.C) in order to

obtain the correct flow rate of domestic hot water for the specific boiler

output.

FLOWSWITCH

This device gives precedence to domestic hot water and is fitted to boilers

which supply instantaneous hot water (see fig. 2, item B fig. 3). It allows

conversion to hot water even with a minimum hot water demand (2

litres/min.), using an electromagnetic principle with electrical switching by

means of a relay. The device is made of non-toxic, corrosion-proof ZYTEL

101 L plastic material which has type approval with non-toxic characteristics

and is unaffected by hard water. In addition, a filter is fitted before the

flowswitch and at the cold water inlet which eliminates any water impurities.

These features guarantee that the flowswitch operation is highly efficient.

BY-PASS

All boilers are fitted with a by-pass. This element is essential in the following

cases:

#

if a two-way zone valve is installed

#

if thermostat valves are installed in the radiators.

To adjust the by-pass proceed as follows (see fig. 3 pos.A): fit the screwdriver

to the plastic screw of the by-pass, bearing in mind that when the slot of the

screw is horizontal the by-pass is totally open, allowing all the water to pass,

while when it is vertical the by-pass is totally closed. For partial by-pass flows,

use the adjuster screw.

D.H.W. CIRCULATING LOOP

It is possible to make a d.h.w. circulating loop. Please proceed as follows:

unscrew CAP A on the cylinder top,, insert a stainless steel PIPE B (supplied

by the manufacturer with a kit) into the ½” union and connect here the

circulating loop pipe C. If necessary, fit an expansion vessel (as shown in fig.1)

inserting a “T” connection between the circulating loop pipe and the cylinder ½”

union.

A

C

B

1

3

2

4

Flowswitch

C

B

A

Fig. 1

Fig. 2

Fig. 4

Fig. 3

Содержание RMA

Страница 2: ......