Installation Manual

Wall Hung Boiler with D.H.W. Storage Cylinder Low Nox – Cod. 99881NA – July 2001

16

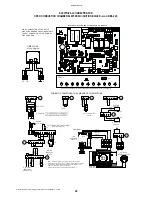

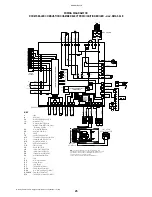

ELECTRICAL CONNECTION

2

1

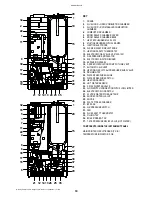

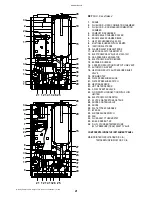

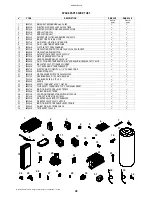

TECHNICAL DATA

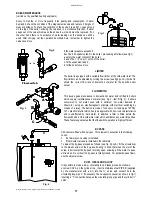

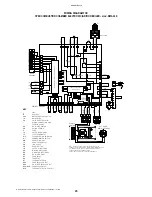

DIFFERENTIAL AIR PRESSURE SWITCH FOR FAN CONTROL

To guarantee maximum safety in flue exhaust, a differential pressure switch is

installed on room-sealed boilers and on forced draught boilers. This pressure

switch automatically controls perfect functioning of the fan and the passage of

both external air and exhaust flue pipes.

Natural draught boilers are equipped with a device (see fig. 1) to control correct

exhaust of combustion gases. This device guarantees maximum safety of

operation if the flue should become partially or totally blocked, or if its section is

not suitable for exhaust of combustion gases.

Before resetting the device, check the exhaust flue section and make sure there

are no. blockages obstructing the correct escape of fumes.

N.B.

It is strictly forbidden to tamper with the device.

RESETTING

:

before resetting the thermostat, carry out the following

operations:

•

turn off the main power supply switch;

•

turn the summer-winter selector switch to the OFF position, detach the

electrical connection (1) on the flue safety thermostat (see fig.1), press

the button (2) between the two electrical contacts and then attach the

electrical connection 1 again.;

•

turn the main power supply switch on again and set the summer/winter

selector switch to the position required.

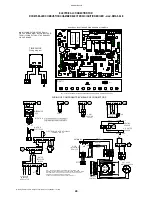

DIVERTER VALVE VC 6012MG6000

The diverter valve is the device which controls the boiler switching from

central heating to d.h. water circuit and vice versa. The diverter valve is fitted

with a manual command lever C (fig. 3) which, when set on the top position,

towards the valve head, allows the boiler operating on the domestic hot water

circuit while, when set on the low position, the boiler operates on the central

heating circuit.

When the C lever is set on the central position, it allows the actuator on

midway.

In this position,

to be used only in case of motor failure or damage

, both

central heating and domestic hot water ports are open and both domestic hot

water and central heating circuits are operating.

To restore the initial position, separate the actuator and the valve body

following instructions from no.1 to no.4 (see fig.2).

To separate the motor from the valve body proceed as follows (fig.2):

1.

Press button A under the motor.

2.

Simultaneously keep the A button pressed and turn the actuator counter-

clockwise;

3.

Lift off the motor

4.

To disconnect the power supply cable press the B tap located on the pin C.

See fig. 4 to perform the electrical wiring of the diverter valve to the main printed circuit board.

DOMESTIC HOT WATER PRODUCTION

The boilers are designed and built for the production of domestic hot water with a 25 lt. capacity storage tank. One advantage of

this system is the amount of water immediately available, thanks to the large exchanger surface of the coil inside the boiler

which allows different services to be used simultaneously.

As well as the use of a porcelain treated glass coating on both the coil and the internal boiler surface to guarantee high levels of

hygiene, the inside of the boiler also has a magnesium anode which, in the event of galvanic currents, preserves it from

corrosion to ensure it a longer working life.

FLUE SAFETY THERMOSTAT

Fig. 1

-

Common

-

D.H. Water

-

Central Heating

CENTRAL HEATING SETTING

M5 TERMINAL

RAMIRE P.C. BOARD

light-

bl

ue

D.H. WATER SETTING

bl

ac

k

br

ow

n

Light-blue

Brown

Black

Fig. 2

Fig. 3

Fig. 4

Содержание RMA

Страница 2: ......